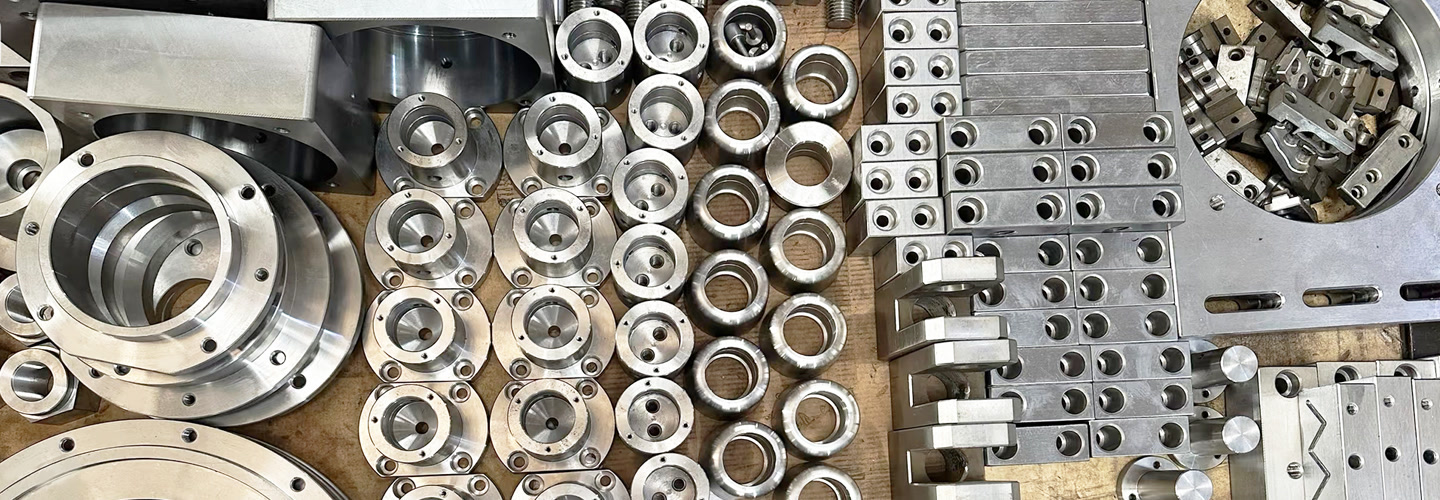

CNC machining (Computer Numerical Control machining) is a precise and efficient method for producing parts across various industries. From prototyping to large-scale production, it delivers flexibility and accuracy. As competition grows, choosing the right material is crucial for balancing quality and cost-effectiveness in CNC machining projects.

What is CNC Machining?

CNC machining is an advanced manufacturing process where computers control tools to create complex and precise parts. It's widely used in energy, automotive, electronic, and consumer goods industries. The choice of material plays a critical role in determining the success of your project, as it affects performance, cost, and processing efficiency.

Key Factors for Choosing CNC Materials

When selecting materials for CNC machining, consider these important factors:

Part Purpose: Understand where the part will be used. Does it need to withstand corrosion, high temperatures, or heavy loads?

Processing Ease: Some materials are easier to machine than others. For example, aluminum and brass are simpler to work with compared to steel or titanium.

Material Properties: Look at strength, stiffness, toughness, heat resistance, and corrosion resistance.

Cost and Availability: Cheaper and readily available materials can save time and money.

Quality Requirements: Ensure the material meets the functional needs of the part.

Common CNC Machining Materials

Here's a breakdown of some popular materials used in CNC machining:

Aluminum

Characteristics: Lightweight, corrosion-resistant, and easy to machine.

Popular Grades:

6061: A versatile option often used in consumer electronics and automotive parts.

7075: Stronger and ideal for high-stress applications.

5052: Excellent for marine and automotive components due to its corrosion resistance.

Stainless Steel

Characteristics: Corrosion-resistant, strong, and durable.

Popular Grades:

303: Easy to machine and perfect for precision parts.

304: General-purpose and great for food and chemical industries.

316: Highly resistant to corrosion, especially in marine environments.

Low-Carbon Steel

Characteristics: Affordable, easy to machine, and good for welding.

Popular Grades:

1018: Suitable for gears and shafts.

1045: Stronger and better for high-load parts.

Brass

Characteristics: Easy to machine, corrosion-resistant, and conducts electricity well.

Popular Grades:

- C36000: Strong and commonly used in electronics and automotive parts.

Plastics

Characteristics: Lightweight, chemically resistant, and insulating.

Popular Types:

ABS: Ideal for prototyping and consumer electronics.

Nylon: Strong and wear-resistant, great for gears and bearings.

Delrin (POM): High mechanical strength and stability, suitable for precise parts.

Factors Affecting CNC Machining Costs

To keep costs under control, consider these key elements:

Machining Time: More complex designs take longer to produce, increasing costs.

Setup Costs: These include planning, programming, and machine preparation. For small batches, these costs can add up quickly.

Raw Material Costs: The price of the material and its machinability directly impact the overall cost.

Post-Machining Processes: Surface treatments like painting or oxidation can increase expenses.

Tool Wear: Harder materials may cause faster tool wear, leading to higher maintenance costs.

Tips to Reduce CNC Machining Costs

Here are ten practical tips to help you save money on CNC machining:

Choose the Right Machine: A 3-axis machine is usually cheaper than a 4- or 5-axis one.

Pick Affordable Materials: Use materials that meet your needs without overspending.

Order in Bulk: Larger orders spread out setup costs, reducing per-part expenses.

Optimize Surface Finish: Avoid overly smooth finishes unless necessary.

Limit Surface Treatments: Only apply coatings or finishes when required.

Set Tolerances Wisely: Tight tolerances only where needed can save costs.

Avoid Thin Walls: Thin walls are harder to machine and prone to deformation.

Use Rounded Corners: Sharp corners require more time and effort to machine.

Minimize Deep Cavities: Deeper cavities mean more material removal and longer machining times.

Control Thread Length: Longer threads increase both cost and potential defects.

Client Case Study

Here are some examples showcasing our ability to deliver efficient, cost-effective, and tailored solutions to meet each client's unique needs.

Furniture Manufacturing

We helped a furniture maker use aluminum for chair frames through optimized CNC machining, boosting efficiency by 40% and reducing costs.

Automotive Industry

Partnering with an automotive supplier, we applied 4-axis machining for stainless steel parts, cutting production time by 35%.

Industrial Equipment

For an industrial equipment company, we used POM (Delrin) for gears, improving durability and lowering material costs.

Selecting the Right CNC Machining Method

In CNC machining, selecting the appropriate method is crucial and depends on factors such as the part's purpose, material machinability, cost constraints, and quality requirements. Making informed decisions in this area can greatly improve efficiency while reducing overall costs. Below is a brief overview of the most common CNC machining methods and their ideal applications:

3-axis CNC: Best for simple, budget-friendly projects that require straightforward designs.

4-axis CNC: Suitable for parts needing rotational symmetry, adding an extra axis of movement for more complex features.

5-axis CNC: Ideal for creating highly intricate geometries with tight tolerances, ensuring superior precision for demanding applications.

Conclusion

Choosing the right material and CNC machining method is crucial for cost-effective, high-quality results. Consider part requirements, material properties, and machining complexity to optimize your projects. Our case studies prove that smart choices save time and money.

Contact us to elevate your CNC projects, or follow us for expert tips and updates!