Transforms metal sheets into enclosures, brackets, and chassis through laser cutting, bending, and welding. Delivers cost-effective solutions for electronics, energy equipment, and automotive components with ±0.1mm precision and fast lead times.

Sheet Metal Fabrication Services

Sheet metal fabrication is ideal for producing high-precision components such as panels and brackets, with custom parts ready in just 5 days. Certified ISO 9001, we offer a variety of metal materials, one-stop solutions, and a cost-effective fast turnaround. With over a million parts produced, we ensure quality and efficiency for both prototypes and large-scale production.

Comprehensive Sheet Metal Fabrication Services

Rapid and affordable sheet metal fabrication transforms materials like aluminum, steel, stainless steel, zinc, copper, and brass into intricate parts and assemblies. This process integrates various techniques such as cutting, bending, punching, stamping, welding, and finishing to achieve the desired outcome. By leveraging these complementary methods, we ensure the successful completion of projects across a wide range of industries, including automotive, aerospace, energy, and robotics, as well as for both industrial and consumer applications. Our services provide versatility and precision, making us a reliable choice for all your sheet metal needs.

Various Techniques in Sheet Metal Fabrication

Cutting

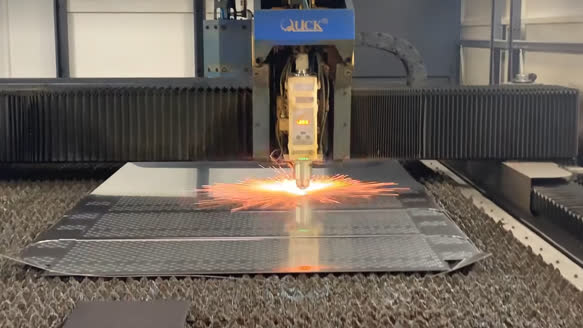

Laser Cutting

Laser sheet metal fabrication or laser cutting utilizes a high-power density laser beam to cut metal materials into desired shapes. This precise method is widely used across various industries for its accuracy and efficiency in producing complex and intricate designs.

Waterjet Cutting

Waterjet cutting employs high-pressure water jets, often mixed with abrasives, to cut through metal sheets. It's particularly effective for cutting low-melting-point metals without causing thermal distortion.

Plasma Cutting

Plasma cutting involves creating an electrical pathway using ionized gas to produce a jet of hot plasma capable of penetrating thick-gauge sheet metal. Known for its cost-effectiveness, this method is ideal for rapid and efficient cutting of thicker materials.

Bending

The sheet metal bending process uses a wedge-shaped tool (die) to apply pressure on a sheet of metal, pushing it into a V-shaped opening to achieve the desired angle. This method is essential for forming enclosures, frames, and other components requiring specific angles or curves.

Stamping

Sheet metal stamping presses flat metal sheets (often from coils) through dies to form parts of the desired shape. This process is commonly used in mass production settings to create identical components efficiently.

Welding

Sheet metal welding joins heated and melted sheet metal parts together, either to increase their strength or to create a single integrated product. Techniques include spot welding, arc welding, and others, each chosen based on material type and application requirements.

Punching

Punching uses dies to punch holes or other shapes into metal sheets. This technique is valuable for creating both decorative designs and functional openings. By applying pressure through a die, specific shapes can be accurately removed from the metal sheet, enabling detailed customization for various applications.

Available Sheet Metal Fabrication Materials

Regardless of your sheet metal parts’ application scenarios and specifications, you can always discover the perfect material at Yes Prototype. Some widely used materials available for custom sheet metal fabrication are outlined below:

Steel

Steel 1018 ,Steel 1045,Steel A569,Steel A36,Steel A366/1008,AZ55,A653,1095 Spring Steel;

Stainless Steel

Stainless steel 301,Stainless steel 304,Stainless steel 316/316L;

Aluminum

Aluminum 1100,Aluminum 5052,Aluminum 6061;

Copper

Copper 101,Copper C110,Copper 260;

Bronze

Bronze 220,Bronze 510;

Titanium

Titanium (Grade 2),Titanium 6AI-4V (Grade 5);

Nickel Alloys

Inconel 625,Nickel Alloy 200,Nickel Alloy 400;

Surface Treatment Services

Surface treatment plays a crucial role in custom sheet metal fabrication, offering both functional and aesthetic enhancements to the finished parts. Below are several surface treatment options available for sheet metal fabricated parts:

Anodizing

Anodizing enhances aluminum parts by improving their resistance to corrosion, wear, and hardness while also protecting the surface from damage.

Bead Blasting

Bead blasting creates a smooth, matte finish on parts, providing a uniform texture that is both appealing and functional.

Electroplating

Electroplating can serve multiple purposes including enhancing functionality, adding decorative finishes, or providing protection against corrosion. Common applications include chrome and nickel plating on steel automotive components.

Powder Coating

Powder coating involves applying a free-flowing, dry powder to the part's surface using electrostatic charge, followed by curing through heat or UV light to form a durable, even coating.

Polishing

Polishing generates a smooth, reflective surface on parts through mechanical friction or chemical reactions, resulting in an visually attractive and high-quality finish.

Brushing

Brushing employs abrasive belts to create distinctive lines on the material's surface, typically for decorative reasons, giving the part a unique textured appearance.

Tolerances and Standards

To ensure the manufacturability of parts and the precision of prototypes, our custom sheet metal fabrication services comply with the ISO 2768-M standard. We automatically break and deburr sharp edges unless specified otherwise.Proper tolerances in sheet metal work are essential for ensuring that parts fit and function correctly. Here are some common tolerances you might expect:

Bending Angle Tolerance

Typical Range: ±1 degree. This means that the angle formed during bending will not deviate more than 1 degree from the designed angle.

Cutting Edge Straightness

Typical Range: Depending on the cutting method (laser, waterjet), it generally falls between ±0.1 mm and ±0.5 mm. Laser Cutting: High precision, typically within ±0.1 mm. Waterjet Cutting: slightly larger tolerance, usually between ±0.2 mm and ±0.5 mm.

Hole Diameter Tolerance

Typical Range: Varies from ±0.1 mm to ±0.3 mm based on the hole size. Smaller holes have tighter tolerances, while larger holes may have slightly looser tolerances.

Material Thickness Tolerance

Typical Range: The actual thickness of the sheet can vary slightly from its nominal thickness. For thin sheets (under 3 mm), expect a tolerance of around ±0.1 mm. For thicker sheets (over 3 mm), this tolerance may increase to ±0.2 mm or more.

Flatness Tolerance

Typical Range: From ±0.5 mm per meter to ±2 mm per meter. This refers to how flat the surface is over a distance of one meter.

Why Choose Us For Sheet Metal Fabrication?

Yes Prototype is a leading sheet metal manufacturer in China. We offer services from prototyping to assembly, ensuring top quality with advanced equipment and cutting-edge techniques. Our focus is on technical excellence, versatility, and flexibility to meet your specific needs, producing affordable, reliable products that respond to customer requirements.

24/7 Engineering Support

Our expert engineers can offer the best solution for your part design, material selection, and surface treatment options, and they are available around the clock.

Guaranteed High Quality

As a sheet metal fabrication facility with ISO 9001:2015 certification, we are able to offer material and full-size reports of inspection over demand.

Quick Turnaround

We know how crucial timely delivery is. With our local workshop and advanced machinery, we can quickly produce your prototypes or parts, ensuring fast turnaround times without compromising on quality.

One-on-One Support

Receive personalized one-on-one assistance, with prompt responses within 24 hours and constant attention to the specifics of your request. From beginning to end, you will have an excellent customer experience.

Comprehensive Capabilities

Leverage our comprehensive production capabilities, which include in-house manufacturing and surface treatment services. By integrating our manufacturing resources, we provide a seamless and efficient production process.

Cost-effective Solutions

We provide competitive pricing and cost-effective solutions by streamlining our production processes. This enables us to deliver high-quality sheet metal fabrication that is both affordable and reliable.

Design Considerations for Sheet Metal Fabrication

With years of experience in sheet metal manufacturing, Yes Prototype has summarized the key design features to consider when creating sheet metal parts:

Wall Thickness

Uniform thickness is essential for high-quality parts. Varying thicknesses can cause alignment issues and increase production time. Ensure consistent material thickness to meet specifications.

Bend Radius

Keep the internal bend radius at least equal to the material thickness to avoid warping and cracking. Consistent radii improve cost-effectiveness and structural integrity.

Bend Allowance and Deduction

Bend allowance adds extra material for flat patterns. Bend deduction removes material from flange lengths to achieve accurate flat patterns.

K-Factor

The K-Factor determines the ratio of the neutral axis to material thickness, varying by material properties. Knowing this value is crucial for precise bends.

Orientation of Holes and Slots

Holes and slots should be at least as large as the sheet metal thickness. Space them reasonably and keep away from edges. Consider additional features like flanges, notches, and fillets.

Edge Treatment

Edge treatments like hemming, debarring, or rolling enhance safety and durability. Hemming strengthens edges; deburring smooths rough edges; rolling improves appearance and strength.

Joining Methods

Choose the right joining method for structural strength. Welding creates strong joints; riveting allows disassembly; bolting offers flexibility for maintenance. Select based on application needs and material properties.

Get Started on Your Sheet Metal Project Today

After receiving your CAD drawings, our engineers will analyze your custom parts immediately. We'll work closely with you to clarify all details before providing a quote that is both economical and accurate.