Produces rotationally symmetric parts (e.g., shafts, connectors) by precision-cutting rotating workpieces. Delivers high-volume cylindrical components with consistent wall thickness for hydraulic systems and machinery assemblies.

CNC Turning Services

From Prototype to Low-Volume Production

At Yes Prototype, our CNC turning service is dedicated to producing complex geometries and features from plastic and metal, suitable for both prototyping and small-scale manufacturing projects.

What Is CNC Turning?

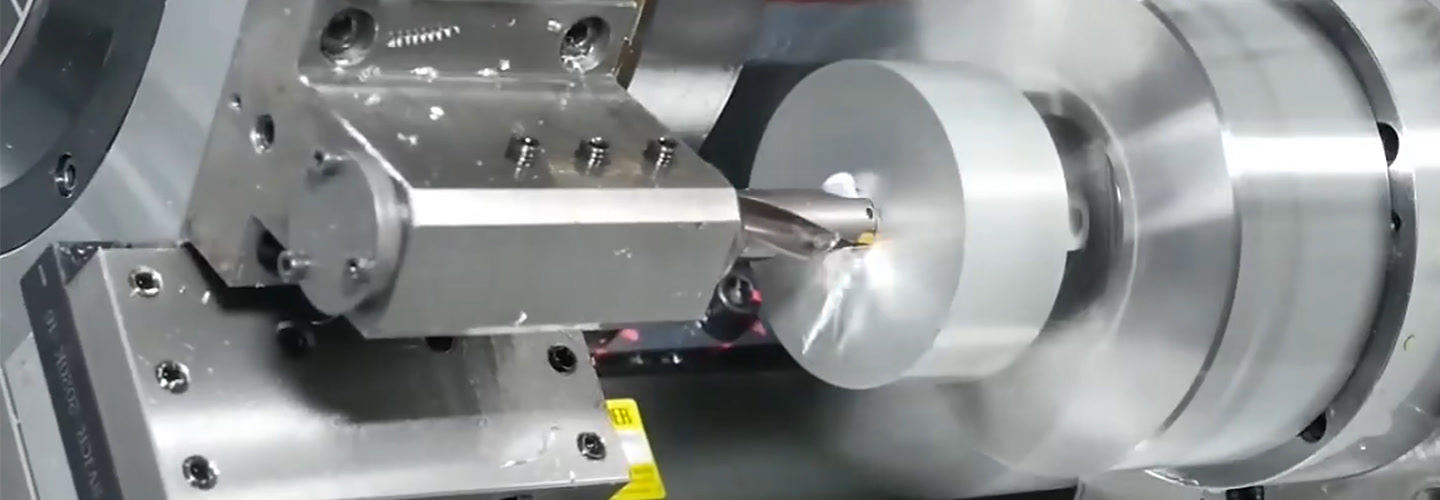

Turning is the process where material is removed from a rotating workpiece to create a finished or semi-finished part. Guided by your 3D file, it is optimized to translate your digital design into a physical component.

In CNC turning, the workpiece is clamped into a rotating spindle, while the cutting tool, mounted on a stationary turret, moves along linear paths. The spindle rotates the workpiece, allowing for precise material removal and the creation of a wide range of complex shapes and part features. Multi-axis turning centers offer significant advantages through the independent movements of the worktable and spindle, ensuring precision, repeatability, and versatility.

What Kind of Materials Can Be CNC Turned?

While virtually any solid, stable material can be turned, we offer a standard selection of raw materials, including hard plastics and aluminum, as well as various types of steel, titanium, magnesium, brass, copper, and other alloys.

Please note that some tool steels may be too tough to cut on a lathe or might require special treatment and extended processing times. Similarly, soft elastomers or plastics that cannot maintain a fixed position or deform under the pressure of the cutting tool may not be suitable for turning.

Why Choose Us ?

24/7 Engineering Support: Experienced engineers provide the most suitable solution for your part design, material selection, and surface treatment options.

Optimize Cost Efficiency: We keep costs down while providing precision and quality without compromises.

Precision Tolerances: Full size and material inspection reports can be supplied. Our custom CNC turned parts can achieve tight tolerances as precise as ±0.005 mm where needed.

Quality Control: Incoming raw materials are carefully inspected and tested to ensure they meet your specifications, guaranteeing the quality and reliability of our supply chain.

Rapid Prototyping: We specialize in rapid prototyping and low-volume manufacturing, with quick setups and fast production cycles as part of our core capabilities.

Worldwide Delivery: Located near major shipping ports in Shenzhen, we can expedite the delivery of your parts worldwide.

Get Your CNC Turning Project Started Today

With a variety of finishing options and strict inspection services, you can trust us to deliver high-quality parts. When we receive your 3D CAD file, our customer service engineer will review your design for manufacturability to ensure it meets your expectations and budget requirements.