Bonds substrates (metal/plastic) with TPE/TPU layers for ergonomic grips, waterproof seals, or vibration dampening in power tools and wearables. Enables multi-material integration in a single cycle via sequential or co-injection processes.

Overmolding Services

What is Overmolding?

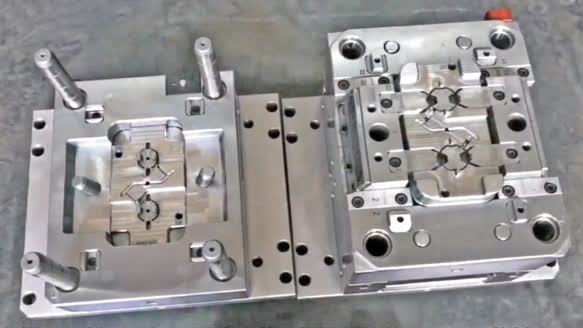

Overmolding is a manufacturing process that creates a single component by partially or completely encasing one material in another. The base material can be molded plastic, CNC-machined metal, or pre-made goods such as screws and threaded inserts. The overmolding material, typically a type of rubber or plastic mixed with colorants and blowing agents, is heated until it melts and then poured into molds in liquid form. This technique allows for the production of complex shapes and multi-material components. Overmolding not only improves product comfort and performance but also effectively satisfies material, performance, and exact tolerance requirements without increasing production costs or duration.

It offers a cost-effective method with faster turnaround times by eliminating the need for extra assembly steps, thus enabling products to reach the market sooner. This efficiency makes overmolding an excellent choice for reducing overall production costs and accelerating time to market.

Advantages of Overmolding

Enhances Functionality and Comfort Overmolding improves function and comfort by creating soft-touch handles, as seen in surgical instruments. Aesthetic Customization It allows for molding multiple colors onto a product, enhancing its aesthetic appeal or branding. Reduces Manufacturing Costs By eliminating the need for secondary assembly steps, overmolding helps reduce overall production costs. Increases Strength and Durability Overmolding can enhance the strength, durability, and aesthetics of plastic parts, while also adding new functionalities like grippy surfaces or watertight seals.

Types of Overmolding

Different types of overmolding cater to various needs, making it a flexible option for enhancing part performance and design. The four primary types of overmolding include:

Plastic-over-Plastic: Adds an additional layer for increased strength or visual appeal.

Rubber-over-Plastic: Uses rubber to improve grip or create a watertight seal.

Plastic-over-Metal: Coats a metal core with plastic to enhance durability or aesthetics.

Rubber-over-Metal: Applies rubber to metal to improve durability or grip. This range of options enables designers and engineers to choose the most suitable method based on their project's specific requirements.

Materials for Overmolding

Depending on your project's geometry, complexity, and needs, Yes Prototype provides a range of materials for overmolding. These materials fall under three different groups, which include: Rigid Plastics(ABS,Polypropylene,Polycarbonate Acrylic,Nylon,POM,PTFEPBT/PBT-PC,PEEK,HDPE,PVC,PPS,PI,PAI,UPE/UHMW,PVDF,ULTEM (PEI) Flexible Plastics(PE,PS,PET,EVA Foam,EPS Foam,PU Foam, Rubber Plastics(TPE,TPU,Silicon Rubber)

Overmolding Applications

Overmolding is utilized to produce parts and assemblies for a wide range of industrial applications, serving both domestic and commercial needs:

Toy Manufacturing

Overmolding employs colored resins to produce toy components with seamless designs, boosting both visual appeal and durability.

Automotive Parts

In the automotive field, overmolding reinforces plastic parts and enhances grip, contributing to the safety and reliability of components.

Electronics

Overmolding encases electronic parts in plastic, offering insulation and protection that enhance safety and longevity.

Tools

Overmolding enhances the grip and comfort of tools such as pliers, screwdrivers, and hammers, making them more user-friendly.

Household Products

Overmolding improves grip, hygiene, and usability in everyday items like kitchen tools, toothbrushes, pens, and shampoo bottles, while also enhancing vibration dampening and resistance to chemicals.

Why choose Yes Prototype For Overmolding ?

Expertise in Complex Processes

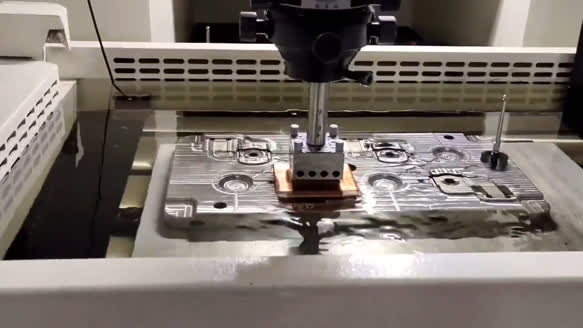

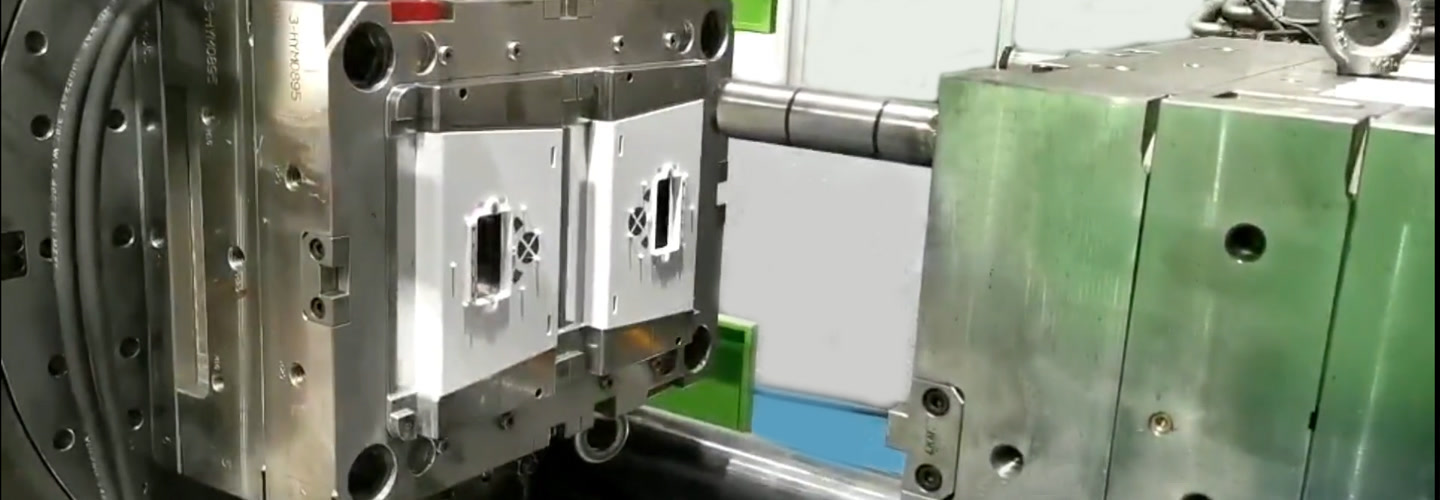

Overmolding is a quite challenging procedure, and every project is unique. We can adapt to many types of overmolding upon request due to our sophisticated injection molding equipment and years of manufacturing experience.while guarantees the products’ reliability and quality.

Ideal Material for Overmolding

For every project, Yes Prototype selects the most suitable resin material to enhance the final product's overall quality and functionality. We ensure that the final parts meet performance, material, and critical tolerance requirements without increasing manufacturing costs or time.

Professional Team Work

Every member of our team, including designers, production engineers, and mold engineers, gets extensive training in injection molding technology.The seamless cooperation of team members guarantees that every plastic part and mold design is optimized for overmolding.

Quality Control and Standards

In order to ensure high quality in our manufacturing process, we adhere to the DIN-16742 standard tolerances for injection molding. Strict ISO 9001 quality control procedures ensure that only the best quality parts are produced. Following strict standards is essential for attaining precision and dependability.

Cost-effectiveness

We utilize advanced automation procedures and advanced techniques to ensure that overmolding projects remain cost-effective, delivering maximum value while fitting within your budget.

Comprehensive Services

Each product design project includes a thorough review to identify potential issues such as material compatibility in overmolding. Our meticulous analysis and strict process control ensure smooth progress from concept to completion with faster lead times and quick turnaround while saving time and money.

Request a Quote for Overmolding Today

After receiving your 3D drawings, our engineers will analyze your custom parts immediately. We’ll work closely with you to clarify all details before providing a quote that is both economical and accurate.