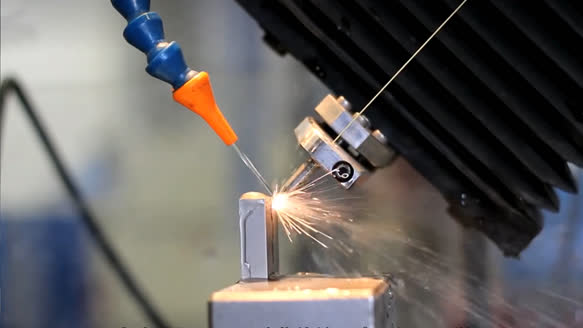

Shapes hardened metals via controlled electrical sparks, achieving intricate details in tooling inserts and micro-mold cavities. Solves challenges for high-hardness alloys (e.g., tungsten) unreachable by traditional cutting tools.

EDM Machining Services

From Prototype to Low-Volume Production

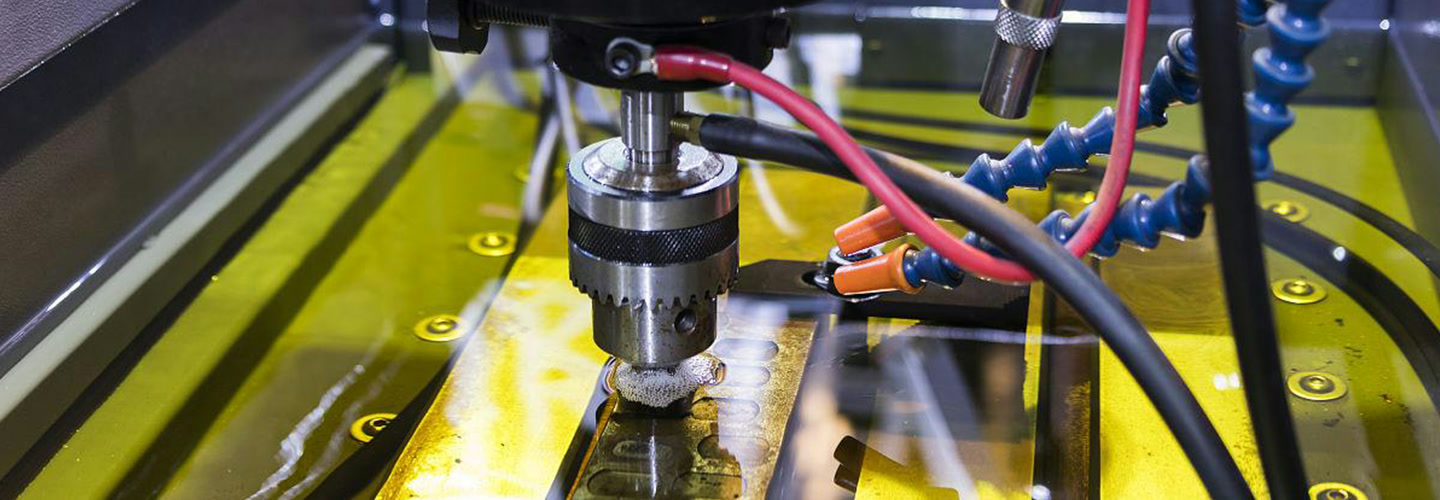

Yes Prototype specializes in precision EDM Machining, including Sinker EDM, Wire EDM, and Hole Drilling EDM ect. Advanced machinery and technology enable cost-effective production of custom, small, and complex parts with exceptional accuracy. Our EDM Machining services are seamlessly integrated with other manufacturing processes, such as turning, milling, grinding, heat treatment, surface coating, and assembly, providing a comprehensive, end-to-end solution for custom part needs.

What Is EDM (Electrical Discharge Machining)?

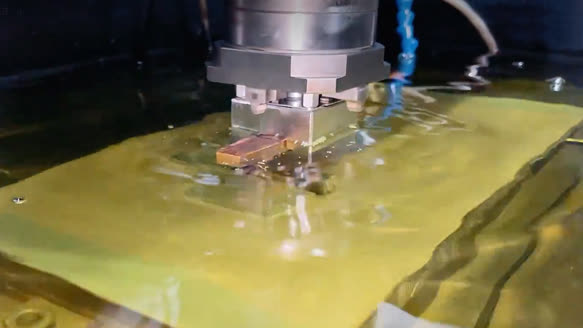

The EDM process is a non-contact machining method that uses electrical discharges to remove material from the workpiece without applying mechanical stress. Ideal for cutting complex shapes and cavities in very hard metals, the EDM process submerges both the electrode and the workpiece in a dielectric fluid. This fluid controls the electrical discharge and flushes away eroded material. Repeated electric currents create tiny plasma zones that instantly melt and remove material, resulting in precise and intricate geometries.

Why Choose EDM Machining?

The EDM process is ideal for producing sharp internal corners, deep cavities, and fine details with exceptional precision and high-quality surface finishes. It excels in machining materials that are too hard for conventional methods or prone to hardening during CNC machining, all while avoiding deformation and tool wear. By using electrical discharges to remove material without applying mechanical stress, the EDM process maintains consistent precision and quality, even when working with hard and heat-sensitive materials.

Suitable Materials for EDM Machining

Virtually any conductive material can be processed by EDM Machining, making it especially effective for machining hard materials that are challenging with traditional techniques, such as tungsten, molybdenum, hardened tool steels, titanium, and austenitic stainless steels. For non-conductive materials like ceramics or plastics, special modifications or coatings are required to enable successful EDM Machining.

Why Choose Us?

24/7 Engineering Support: Experienced engineers provide the most suitable solution for your part design, material selection, and surface treatment options.

Optimize Cost Efficiency: We keep costs down while providing precision and quality without compromises.

Precision Tolerances: Full size and material inspection reports can be supplied. Our EDM process can achieve tight tolerances as precise as ±0.0025 mm where needed.

Quality Control: Incoming raw materials are carefully inspected and tested to ensure they meet your specifications, guaranteeing the quality and reliability of our supply chain.

Rapid Prototyping: We specialize in rapid prototyping and low-volume manufacturing, with quick setups and fast production cycles as part of our core capabilities.

Worldwide Delivery: Located near major shipping ports in Shenzhen, we can expedite the delivery of your parts worldwide.

Request Your EDM Project Quote Today

With a variety of finishing options and strict inspection services, you can trust us to deliver high-quality parts. When we receive your 3D CAD file, our customer service engineer will review your design for manufacturability to ensure it meets your expectations and budget requirements.