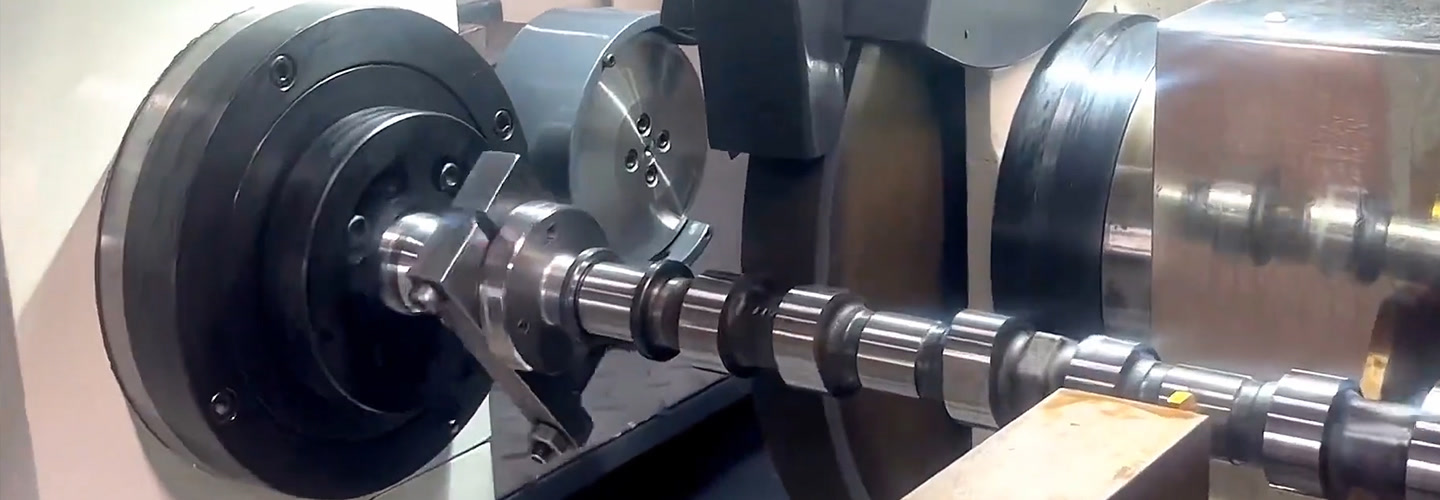

Attains sub-micron surface finishes and ultra-tight tolerances on hardened steel shafts, bearing races, and optical components. Compensates for post-heat-treatment distortions in automotive transmission parts and energy turbine components.

Precision Grinding Services

From Prototype to Low-Volume Production

At Yes Prototype, our Precision Grinding service is dedicated to producing high-precision parts with complex geometries and tight tolerances, suitable for both prototyping and small-scale manufacturing projects. We specialize in a wide range of materials, including metals, plastics, and composites, ensuring that we can meet the unique requirements of each application.

What Is Precision Grinding?

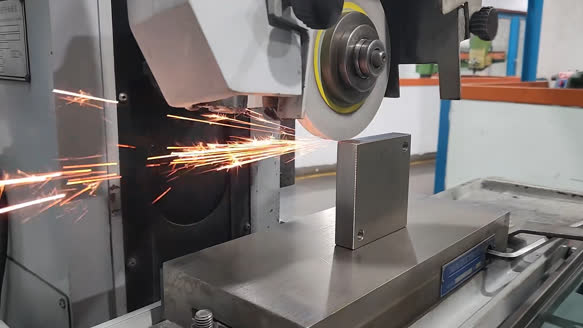

Precision grinding is a machining process that uses specialized grinding wheels to achieve extremely flat surfaces with tight tolerances. This method is ideal for parts requiring exceptional surface evenness and accuracy. Our precision grinding capabilities include:

External Diameter (OD) Tolerances: ±0.001mm

Internal Diameter (ID) Tolerances: ±0.001mm

Roundness: ±0.001mm Cylindricity: ±0.001mm

Surface Finish: 0.6Ra to 0.8Ra

Diameter Range: 0.1mm to 300mm

Types of Precision Grinding

Centerless Grinding (OD): Ideal for large volumes of cylindrical parts, providing fast and accurate outer diameter grinding.

Cylindrical Grinding (OD & ID): Suitable for parts with complex geometries, offering precise grinding of both inner and outer diameters.

Surface Grinding: Ensures flat and parallel surfaces, critical for components requiring high dimensional accuracy.

Profile Grinding: Used for intricate shapes and contours, ensuring exact part-to-part consistency.

Suitable Materials

Our precision grinding services can handle a wide variety of materials, including:

Metals: Stainless steel, aluminum, tool steel, die steel, brass, copper, magnesium, platinum, tantalum, cobalt, and more.

Plastics: ABS, Delrin, acrylic, G-10 Garolite, nylon 6/6, PEEK, polycarbonate, PTFE (Teflon), polypropylene, and others. Composites and Ceramics: Ceramics, composites, ferrite, rubber, and acrylic, among others.

Why Choose Precision Grinding?

One-Stop Solution: Comprehensive services including CNC turning, milling, and finishing etc.

Advanced Equipment: Precision grinding machines for various materials and complex requirements.

24/7 Support: Expert engineers with over 10 years of experience assist with design, material selection, surface treatment, and ensure parts meet exact specifications.

Optimize Cost Efficiency: We keep costs down while providing precision and quality without compromises.

Quality Control: Incoming raw materials are carefully inspected and tested to ensure they meet your specifications, guaranteeing the quality and reliability of our supply chain.

Rapid Prototyping: We specialize in rapid prototyping and low-volume manufacturing, with quick setups and fast production cycles as part of our core capabilities.

Worldwide Delivery: Located near major shipping ports in Shenzhen, we can expedite the delivery of your parts worldwide.

Begin Your Precision Grinding Project Today

With a variety of finishing options and strict inspection services, you can trust us to deliver high-quality parts. When we receive your 3D CAD file, our customer service engineer will review your design for manufacturability to ensure it meets your expectations and budget requirements.