Creates soft steel or aluminum prototype molds for 100-5k unit batches, accelerating product validation for IoT devices and tool handles. Cuts lead times by 40% vs. traditional tooling while maintaining ±0.1mm precision.

Rapid Tooling Services

What Is Rapid Tooling?

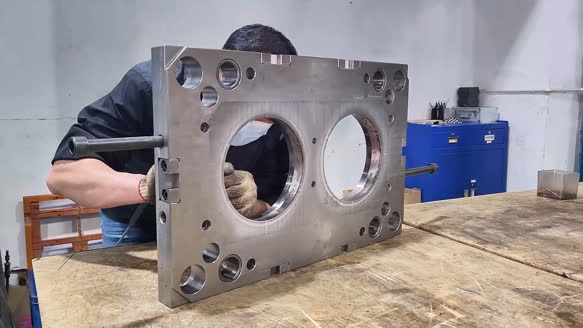

Rapid tooling is a specialized service for producing certain types of plastic injection mold tools and finished parts in a small portion of the time needed for full-production volume tools. These molds use standard plastic resins and fillers to make fully functional finished parts in relatively limited quantities. This approach optimizes design, fabrication processes, and material selection to maximize production efficiency while minimizing downtime.

Mold Materials for Rapid Tooling

P20 steel is durable and efficient for high-volume production, while aluminum provides faster cycle times and lower costs but is less durable.

P20 Steel for Tooling

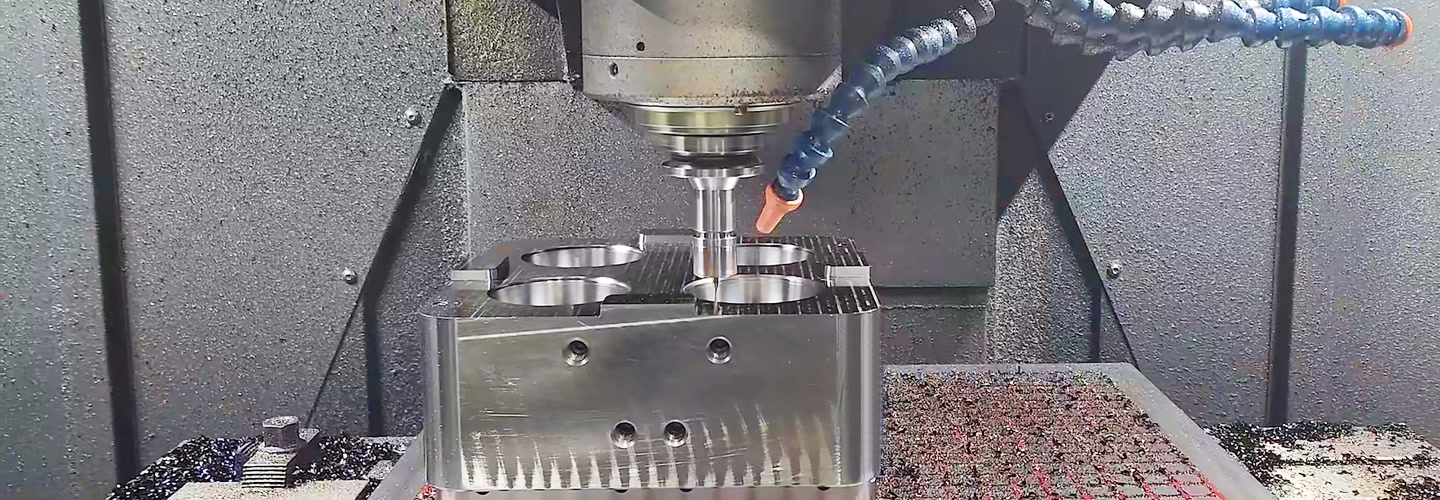

P20 steel is widely used for rapid production tooling due to its durability and reliability. It can be easily machined with standard tools and does not require post-machining heat treatment, which makes it a ‘semi-hardened’ option. P20 steel provides an excellent surface finish and consistent performance, allowing for the production of high-quality tools that can yield a higher volume of finished parts over time. However, its lower thermal conductivity can result in longer cooling times compared to aluminum, potentially extending production cycles.

Aluminum for Rapid Tooling

Aluminum is a cost-effective choice for rapid tooling, offering excellent dimensional stability that helps reduce waste and part deformation. Its ease of machining can lower tooling costs by about 20%, and its high thermal conductivity can decrease cycle times by 25-35%. However, aluminum molds are less durable than P20 steel molds, which limits their lifespan and production capacity.

Advantages of Rapid Tooling

Finished parts can be used for prototypes, product testing and certification, and as bridge production towards higher volumes. Rapid tooling injection molding also helps our clients to limit their financial exposure to new designs.

Limitations Of Rapid Production Tooling

To get quick results, there are several constraints to the kind of tools and parts that can be created using this method. These limits do not imply that you will receive an inferior tool. Rather, we reduce the development process to obtain the shortest production lead time at the lowest cost.

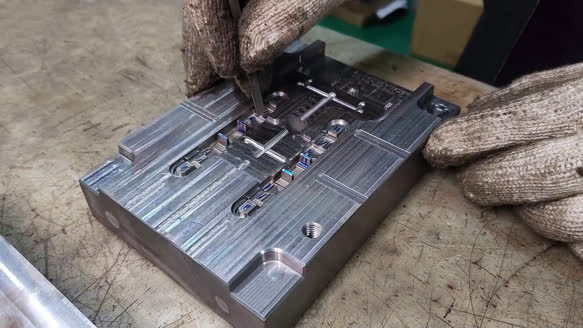

Simplified Tooling Design

Rapid tools consist of two-part molds, each containing a maximum of two cavities. This design eliminates the need for additional sliders or hand-loaded inserts. The geometries involved should be straightforward, avoiding intricate gate/runner systems or complex cooling channels. Simple geometries allows for the implementation of basic ejector pin strategies, and there is no requirement for advanced molding process analysis tools.

Modular Inserts

The inserts are specifically machined to fit into standard mold bases, facilitating efficient manufacturing while minimizing material consumption.

Cooling Circuits

Our cooling circuits utilize standard cold runners instead of hot runners.

Surface Feature

Rapid tools feature as-machined surfaces, with just minor polishing or bead blasting done.

Tolerance Standard

The tools are manufactured to meet DIN-2768-1-fine tolerance standards.

Why Choose Yes Prototype for Rapid Tooling?

Design for Manufacturing (DFM) Support

For every project, we provide design for manufacturing (DFM) support, offering insights about design improvements that make manufacturing easier, reduce costs, and shorten production lead times. Additionally, we offer detailed video files showing all production steps, along with video conferencing and general support as needed.

Quality Assurance and Inspection

We carefully inspect all incoming materials and issue a complete verification analysis at your request. You will receive the sample inspection report and samples to confirm all dimensions and tolerances for your rapid tools and finished parts.By streamlining the development process for rapid tooling, we ensure high-quality tools and parts without compromising on standards, maintaining the same level of quality and materials used in full-volume production—all while achieving cost savings.

Dedicated Project Management

A dedicated engineer is responsible for your tool from start to finish, ensuring the fastest possible turnaround.

Services Support

We offer competitive pricing with no minimum order requirements and deliver quotes within 48 hours.

Start Bringing Your Ideas to Life Today

After receiving your 3D drawings, our engineers will analyze your custom parts immediately. We’ll work closely with you to clarify all details before providing a quote that is both economical and accurate.