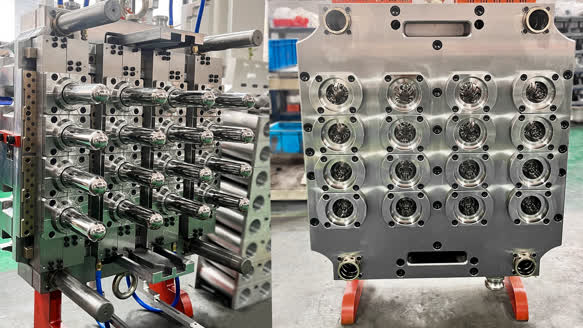

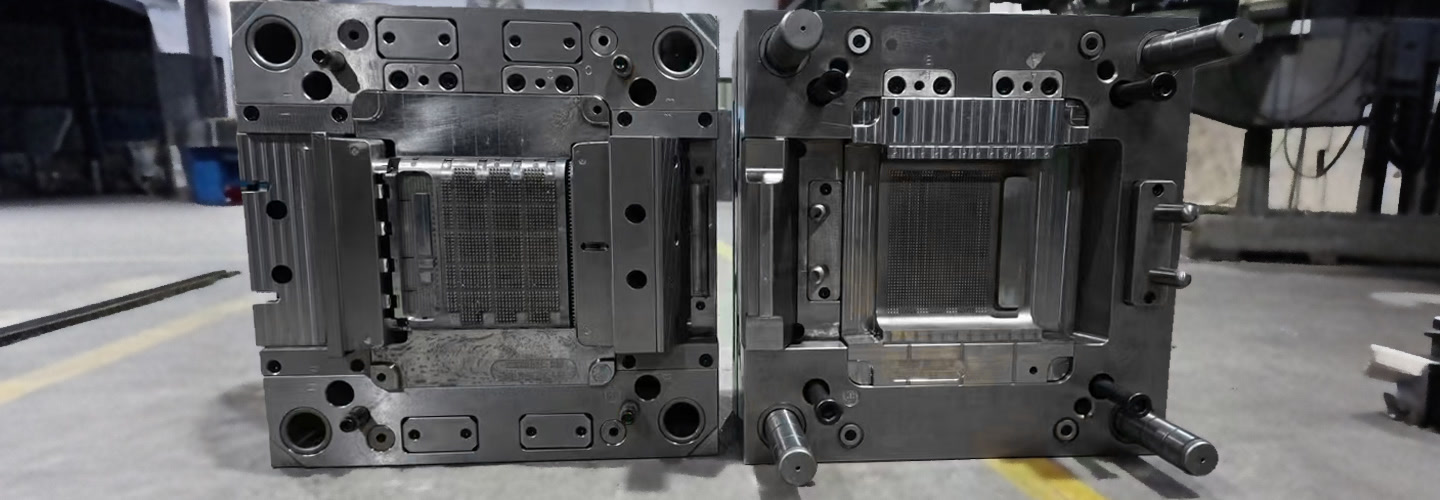

Builds hardened steel/aluminum molds for long-term manufacturing cycles (50k+ shots), optimized for mass production of automotive trim and appliance parts. Features automated ejection systems and conformal cooling channels for cycle time reduction.

Production Tooling Service

Capabilities and Service

Yes Prototype excels in making accurate molds for high-quality plastic parts, providing quality, timely delivery, and competitive prices. To ensure the molds can be used repeatedly without degrading, we employ premium raw materials, smart design, precision machining, and advanced molding process analysis tools. From intricate airplane parts to basic kids' toys, our Production Tooling services cover a wide range of applications.

Expertise in Production Tooling

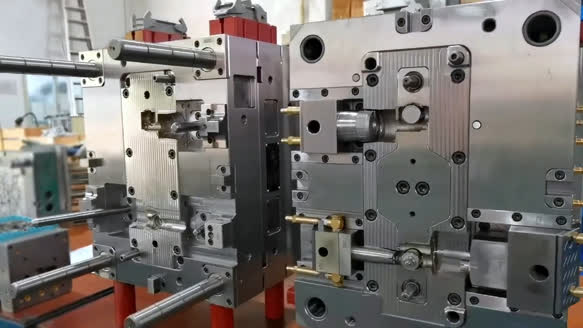

Our team of skilled Production Tooling technicians and experts can manufacture precise plastic injection molds tailored to your requirements. Designed to withstand high-volume production while maintaining tight dimensional tolerances, these molds benefit from our meticulous process control and positive material identification. This ensures consistent and quick cycle times, as well as minimized cost per piece for complex parts and assemblies.

Material Selection for Injection Molds

Each type of material offers varied levels of corrosion resistance, toughness, thermal efficiency, and polishability. Tool design complexity, injected resin type, part surface polish requirements, and expected production quantities all influence the tool steel selection. The quality and service life of the injection-molded part are determined by the material used in the mold. We provide a range of material grades for injection molds utilized at different stages of product development. The materials most frequently used include stainless steel (420, NAK80, S136, 316L, 316, 301, 303, 304), tool steel (P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738), and aluminum, which is substantially less expensive than both stainless steel and tool steel.

Cost Factor of Production Tooling

Production Tooling costs are complex and influenced by several factors, including design complexity, number of cavities, type of mold steel, surface finish, and the use of a hot runner system. Cycle times and cost per piece are important considerations for high-volume production in order to maximize efficiency and minimize overall costs. Multi-cavity molds require a higher initial investment than single-cavity molds due to increased material, labor, and energy requirements; however, this investment may not be cost-effective for small batches, where a single-cavity mold may be more suitable.

Why Choose Yes Prototype for Production Tooling ?

We provide dedicated support and expertise for every project. Our team of engineers, designers, and production experts guarantees dependable, superior service that you can rely on.

Effective Communication

We ensure that everyone on our team understands your needs for large-quantity Production Tooling and final parts. Yes Prototype efficiently produces superior Production Tooling using sophisticated software, skilled designers, and precise CNC equipment.

Precision Manufacturing

We has partnered with thousands of businesses, excelling in precision manufacturing and technical design over the years. Yes Prototype specialize in producing complex Production Tooling for a wide range of industries, including aerospace, automotive, medical, electronics, consumer goods, and industrial equipment. Our experience guarantees accurate, high-quality solutions catered to the particular requirements of every industry.

Positive Material Identification

Scientific test equipment ensures positive material identification. In order to fulfill your essential product certification and licensing requirements, you receive complete material traceability.

Comprehensive Services To complete your project to the highest standards, we provide a comprehensive range of additional services. These include metal stamping, EDM machining, CNC milling and turning, aluminum extrusion, painting, plating, laser etching, light assembly, and more.

Quality Assurance and Precision

We are certified ISO 9001, reflecting our commitment to quality and customer satisfaction through stringent standards and continuous improvement. Our mold cavities are manufactured to achieve tolerances up to ±0.002 mm, ensuring high precision for your parts. We also provide professional DFM reports and comprehensive molding process analysis to help you minimize risks and maximize efficiency.

Get a Production Tooling Quote Today

After receiving your 3D drawings, our engineers will analyze your custom parts immediately. We'll work closely with you to clarify all details before providing a quote that is both economical and accurate.