CNC machining is an automated process for producing mechanical parts, where tolerances ensure they meet design requirements, function correctly, and fit together properly. Below, we explore tolerances, their types, influencing factors, and how to choose the right ones, with practical tips and real-world examples to help optimize your designs.

What Are CNC Machining Tolerances?

CNC machining tolerances refer to the allowable deviation between a part's actual dimensions and its designed dimensions. They are a key measure of part precision, directly impacting functionality and assembly. For instance, a hole designed to be 10mm in diameter might have a tolerance of ±0.01mm, meaning the actual diameter can range from 9.99mm to 10.01mm.

Why Tolerances Matter:

Ensure Functionality: Parts perform as intended.

Improve Compatibility: Parts fit perfectly with other components.

Reduce Costs: Optimized tolerances minimize unnecessary machining time and material waste.

Lower Risks: Strict tolerances are crucial in high-risk industries to prevent safety issues.

How to Choose the Right Tolerances?

Selecting the right tolerances is key to balancing part quality and cost-effectiveness. Here's a step-by-step guide:

Understand Part Function

Define the part's purpose, operating environment, and conditions. For example, parts used in high-temperature environments must account for thermal expansion.

Consider Manufacturing Processes

Different methods have different tolerance capabilities. CNC machining is more precise than injection molding, but the choice depends on the part's complexity and material.

Refer to Industry Standards

Use standards like ISO or ASME as a reference. For instance, DIN-2768-1 is a common standard in mechanical engineering for specifying tolerances.

Test and Analyze

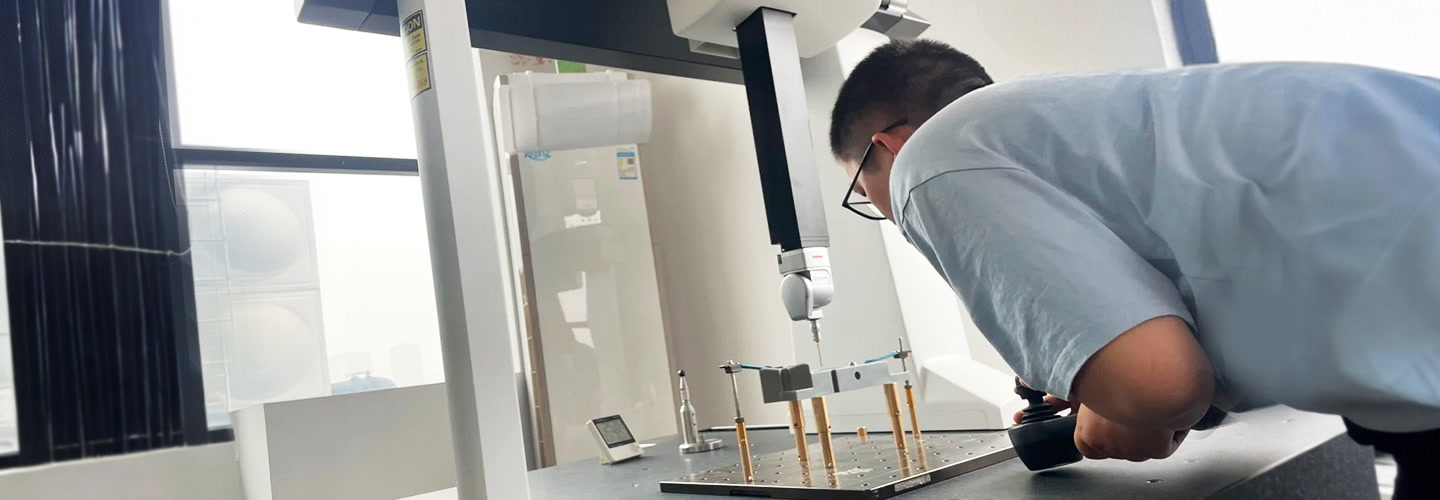

Verify tolerances through dimensional measurements and functional tests. Tools like 3D scanners or coordinate measuring machines (CMMs) can ensure parts meet specifications.

Use Tolerance Analysis Software

Simulate how tolerances affect the overall design to save time and costs. Software can predict assembly outcomes under different tolerance settings, helping you avoid costly redesigns.

Partner with a Professional CNC Machining Service

Work with experienced manufacturers to ensure tolerances are met. At Yes Prototype, we provide expert guidance on tolerance selection, helping you achieve the perfect balance between precision and cost.

Five Key Types of CNC Machining Tolerances

To meet different application needs, CNC machining uses five common types of tolerances:

Dimensional Tolerances

Control the size, shape, and position of a part. A part designed to be 20mm might have a tolerance of ±0.05mm.

Geometric Tolerances

Define the shape and orientation of features like holes, slots, and contours. For example, ensuring the axis of a cylindrical part is perpendicular to a reference surface.

Surface Roughness Tolerances

Manage the smoothness, texture, and roughness of a part's surface. Ra values (arithmetic average roughness) are often used to describe surface quality.

Runout and Concentricity Tolerances

Ensure smooth rotation and alignment of parts. A wheel's center hole must align perfectly with the axle to reduce vibration.

Positional Tolerances

Guarantee precise assembly between parts. Two mating parts must align within a specified range.

Factors Affecting CNC Machining Tolerances

Choosing the right tolerances requires considering several key factors:

Material Properties

Hardness, ductility, and thermal conductivity affect machining precision. Aluminum, for instance, is easier to machine than stainless steel, allowing for tighter tolerances.

Part Geometry and Size

Complex shapes or small parts often require tighter tolerances. Microelectronic components need extreme precision, while larger structural parts can tolerate looser tolerances.

Cutting Parameters and Tools

Cutting speed, tool diameter, and tool wear directly impact tolerance levels. Smaller tools improve precision but increase machining time.

Machine Capability and Calibration

High-precision machines achieve tighter tolerances but require regular maintenance. Advanced 5-axis machines can handle complex geometries with minimal deviation.

Application Requirements

Tolerances should align with the part's intended use and customer specifications. High-performance industries demand higher precision than consumer goods.

Client Case Study

Automotive Industry

We helped an automotive supplier overcome challenges in producing gearbox housing with tight tolerances for a high-performance vehicle. By incorporating T-bone fillets, optimizing toolpaths, and switching to aluminum 7075, we reduced machining costs by 20%, cut lead time by 25%, and ensured the product met all performance requirements.

Consumer Electronics

Partnering with a consumer electronics company, we redesigned a housing component with 0.2 mm fillets, optimized toolpaths, and used aluminum 6061 to achieve precise tolerances. This approach reduced production costs by 25%, cut machining time by 30%, and maintained high-quality performance.

Industrial Equipment

For an industrial equipment manufacturer, we used dog-bone fillets, optimized toolpaths, and selected brass to machine a complex valve housing with strict positional tolerances. This strategy reduced production costs by 30%, cut lead time by 35%, and ensured the final product met all functional and assembly requirements.

Why Choose Yes Prototype for CNC Machining?

We specialize in high-precision CNC machining, delivering top-quality parts tailored to your needs. Here's how we handle tolerances to ensure your project's success:

Precision Expertise: Achieve tolerances as tight as ±0.0002 inches.

Advanced Inspection: Use CMMs and 3D scanners for accurate verification.

Custom Solutions: Tailor our approach to meet your specific needs while optimizing costs and lead times.

Quality Assurance: Follow rigorous quality control processes to ensure every part meets your specifications.

Conclusion

Choosing the right CNC machining tolerances is essential for part functionality, quality, and cost-efficiency. By understanding tolerance types, factors, and selection strategies, you can optimize your designs and improve production outcomes. If you have questions about tolerances or need expert CNC machining services, contact us today! Let's turn your designs into precise, top-quality parts.