For a product to achieve success, it is essential not only to consider its appearance but also to emphasize efficiency and economic viability during the production process.This is where “Design for Manufacturing (DFM)” comes into play. DFM is a systematic approach that ensures your product design aligns perfectly with the manufacturing process, reducing costs and improving efficiency.

What is DFM?

Simply put, DFM is an analytical process used to evaluate whether a product design is suitable for the chosen manufacturing process. By identifying potential issues early in the design phase and making adjustments, DFM avoids costly rework later on.

Why Use DFM?

Cost Reduction

If a design doesn’t meet manufacturing requirements, it may require redesigns or changes to the production process later, significantly increasing time and cost. DFM helps catch these issues early, allowing for timely resolutions.

Improved Quality

DFM fine-tunes designs to better suit manufacturing processes, reducing defect rates and enhancing the final product’s quality.

Faster Production

When a design seamlessly matches the manufacturing process, production flows more smoothly, leading to faster delivery times.

Technical Details of DFM

Common Tools

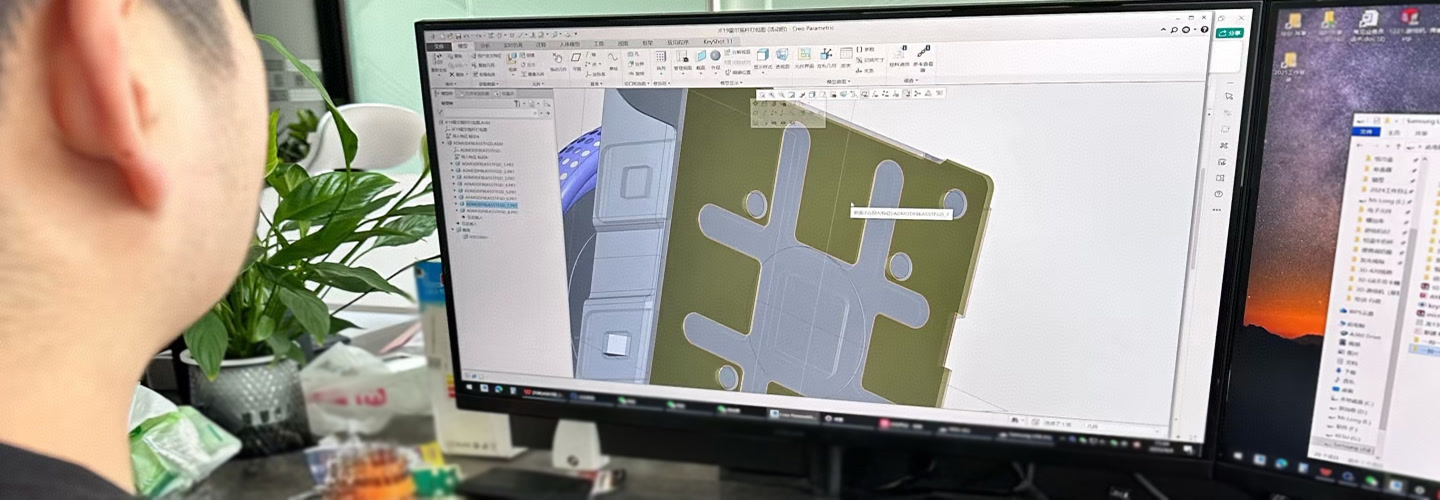

CAD Software: Used for creating and optimizing product models.

Finite Element Analysis (FEA): Predicts stress distribution and helps refine structural designs.

Mold Filling Simulation: Evaluates the feasibility of injection molding and optimizes mold design.

Key Metrics

Tolerances: Ensures the design fits within the capabilities of manufacturing equipment.

Material Properties: Selects materials compatible with the chosen manufacturing process to avoid defects.

Production Efficiency: Optimizes the design to reduce machining time and increase output.

Who Should Be Involved in DFM?

DFM is a collaborative effort involving several key roles:

Designers: Provide the initial product design.

Engineers: Assess the feasibility of the design and suggest improvements.

Material Experts: Choose appropriate materials to meet both design and manufacturing needs.

Production Managers: Ensure the design can be manufactured efficiently using existing equipment.

Key Steps in DFM

Define Objectives

Clearly outline the functional requirements and technical specifications of the product before starting, such as load-bearing capacity or surface finish requirements.

Evaluate Feasibility

Carefully review whether the design aligns with the capabilities of the manufacturing process, such as whether complex geometries require specialized tools.

Propose Improvements

Based on analysis results, make necessary adjustments to the design, such as simplifying complex structures or selecting easier-to-process materials.

Test and Validate

Create prototypes or samples to verify that the optimized design meets expectations.

Practical Examples of DFM in Our Projects

Case 1: Simplifying Electronics Enclosure Design

A consumer electronics client needed help with their product enclosure design. Through DFM analysis, we found that complex curves in the original design made machining difficult and increased costs. By simplifying the design and selecting better materials for injection molding, we reduced costs and improved production efficiency.

Case 2: Optimizing Automotive Brake Discs

For an automotive client, we improved the design of their brake discs by adjusting the cooling channel positions and sizes. This change reduced material waste, enhanced heat dissipation, and extended the lifespan of the parts. The result was a more efficient manufacturing process and higher-quality products.

Industry-Specific DFM Practice

Consumer Electronics

In this sector, DFM focuses on reducing production costs and shortening lead times. For example, simplifying internal component layouts reduces assembly steps and improves automation.

Agricultural Equipment

In agricultural machinery manufacturing, DFM emphasizes durability and adaptability. Agricultural equipment often operates in harsh environments, so designs must consider wear-resistant materials and ease of maintenance. For instance, optimizing tractor components for simpler assembly and choosing corrosion-resistant materials extends equipment life.

Electronics

Electronic product design requires balancing miniaturization with thermal management. Through DFM, circuit board layouts can be optimized, unnecessary connectors removed, and assembly difficulty reduced. For example, adjusting heatsink shapes and positions in LED lighting products ensures effective cooling while simplifying manufacturing.

Energy Industry

Energy equipment, such as wind turbines and solar panel mounts, demands high precision and strength. DFM applications here focus on material selection and structural optimization. For example, simulating and refining blade curvature in wind turbine designs makes them easier to manufacture while maintaining aerodynamic efficiency. Choosing lightweight yet strong materials also lowers transportation and installation costs.

Practical Applications

New Product Development

During development, DFM identifies potential issues early, such as whether the design is easy to manufacture or if the selected materials are appropriate, avoiding costly rework later.

Supply Chain Management

Using DFM to optimize designs allows for more economical material choices and processes, reducing overall production costs. It also minimizes waste and enhances resource utilization.

Customized Production

In small-batch or multi-variant production scenarios, DFM enables quick adjustments to meet customer-specific needs while maintaining high efficiency and quality.

Conclusion

By adopting DFM, you can bridge the gap between product design and manufacturing, achieving greater efficiency, lower costs, and higher-quality results. Whether you’re a designer, engineer, or production manager, DFM is a valuable tool worth mastering.