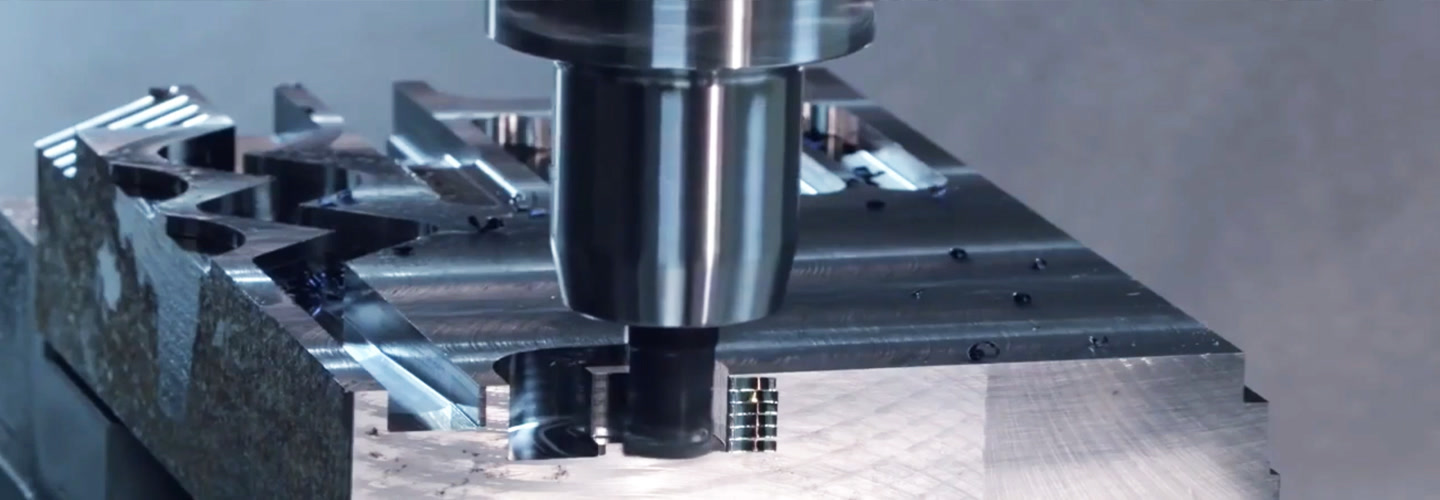

Sharp inside corners are among the most challenging features to achieve in CNC machining. While essential for certain designs, their complexity often leads to higher costs, reduced efficiency, and potential quality issues. In this blog, we'll explore why sharp corners are difficult to machine, how to optimize your designs, and the best strategies to achieve precision when they're absolutely necessary.

Why Are Sharp Inside Corners So Challenging?

CNC machining relies on rotating cutting tools, which are typically cylindrical. This inherent geometry makes it nearly impossible to create perfectly sharp inside corners. Here are the main challenges:

Tool Geometry Limitations: Round tools leave rounded corners, not sharp ones.

Reduced Efficiency: Smaller tools are needed for tight corners, slowing down the machining process.

Chip Removal Issues: Chips can get trapped in sharp corners, affecting surface quality.

Higher Costs: Specialized tools and techniques are often required, increasing production expenses.

Why Avoid Sharp Corners?

Sharp internal corners increase manufacturing complexity, reduce efficiency, and drive up costs. Here's why:

Complexity: Sharp corners require precise tooling and slower machining speeds, making the process more time-consuming and expensive.

Tool Limitations: Cylindrical cutting tools struggle to create sharp internal edges, often leaving rounded corners instead.

Practical Alternatives: Rounded or filleted corners can often serve as functional and cost-effective substitutes without compromising performance.

When Are Sharp Corners Necessary?

Despite the challenges, sharp corners are sometimes essential:

Precision Requirements: Industries like automotive and electronics may require sharp corners for specific functional or assembly needs.

Design Intent: Some products demand sharp corners for aesthetic reasons or to meet market demands.

Functional Benefits: Parts used in tool and die manufacturing or those requiring tight assembly tolerances often necessitate sharp internal features.

Design Tips for Sharp Corners

To avoid these challenges, consider these design optimizations:

Early Design Integration: Incorporate CNC machining considerations early in the design phase to improve manufacturability and reduce costs.

Optimize Toolpaths: Plan toolpaths to minimize tool wear and ensure smooth material removal.

Corner Radius Optimization: Adjust corner radii to match CNC bit diameters, reducing stress on cutting tools.

Tolerances: Maintain a general tolerance of ±0.1 mm to ensure precision while allowing flexibility.

How Material Choice Affects Sharp Corner Machining ?

The material you choose plays a significant role in achieving sharp corners:

Metals: Aluminum is easier to machine than stainless steel or titanium. Harder metals require specialized tools and slower cutting speeds.

Plastics: Materials like ABS and nylon are easier to work with but can deform if overheated.

Composites: Carbon fiber and fiberglass are strong but abrasive, leading to faster tool wear.

Methods for Machining Sharp Inside Corners

Ball-Nose End Mill: Suitable for small-radius corners in softer materials like aluminum or plastics.

Corner Relief End Mill: Effective for precise internal details, especially in mold fabrication.

EDM (Electrical Discharge Machining):

Die-Sink EDM: Ideal for achieving precise sharp corners using custom dies.

Wire EDM: Excels at machining tight radii but is slower and limited to conductive materials.

CNC Routing: Effective for 2D work but may not achieve extreme sharpness.

Laser Cutting: Economical for thin plates but produces small radii instead of perfect square corners.

Alternatives to Sharp Corners

If sharp corners aren't critical, consider these alternatives:

T-Bone Fillets: Simple and effective for parts that need to fit together but lack aesthetic appeal.

Dog-Bone Fillets: More complex but visually appealing, ideal for parts where appearance matters.

Client Case Studies

Consumer Electronics

A consumer electronics client required a housing component with sharp internal corners. By redesigning the part with 0.2 mm fillets, optimizing toolpaths, and switching to aluminum 6061, we reduced machining costs by 25%, cut production time by 30%, and maintained high-quality performance.

Automotive Industry

An automotive supplier needed a gearbox housing with sharp internal corners. By incorporating T-bone fillets, optimizing toolpaths, and switching to aluminum 7075, we reduced machining costs by 20%, cut lead time by 25%, and ensured the product met all performance requirements.

Furniture Manufacturing

A furniture manufacturer needed custom table legs with intricate carvings. By replacing sharp corners with 0.3 mm fillets, optimizing toolpaths, and using CNC routing, we lowered production costs by 15%, reduced machining time by 40%, and maintained the desired aesthetic appeal.

Why Choose Professional CNC Machining Services?

Machining sharp corners requires expertise and precision. Partnering with a professional CNC machining service like Yes Prototype ensures:

High Precision: State-of-the-art equipment and skilled operators deliver accurate results.

Cost Efficiency: Optimized processes reduce waste and lower costs.

Expert Advice: Engineers can recommend the best materials, tools, and techniques for your project.

Conclusion

Sharp inside corners in CNC machining can be challenging, but with the right design, materials, and techniques, they're achievable. For complex projects, partnering with an experienced CNC machining service ensures precision and quality every time. If you're facing similar issues or need expert advice, contact us today ! Let's turn your designs into high-quality, cost-effective solutions. Share your experiences in the comments or reach out to our team for personalized support !