Die casting is a common process that uses high pressure to inject molten metal into molds, creating complex and precise parts quickly. While it produces efficiently and works with various materials, it has limits and challenges that need care. This article covers the basics of die casting, including its types, uses, design factors, and future developments, providing a comprehensive overview of this manufacturing method.

Types of Die Casting Processes

Hot Chamber Die Casting:

This method is ideal for metals with low melting points, such as zinc and magnesium. It offers fast cycle times but isn't suitable for high-temperature materials like aluminum.

Cold Chamber Die Casting:

Used for metals with higher melting points, such as aluminum and copper. While slower than hot chamber casting, it provides greater flexibility for complex parts.

High Pressure Die Casting:

A popular choice for high-precision parts, this technique is commonly used in consumer goods, automotive, and electronics industries. It produces components like engine blocks, cylinder heads, and electronic enclosures with excellent dimensional accuracy.

Vacuum Die Casting:

By creating a vacuum environment, this process reduces air entrapment, improving surface quality and reducing porosity. It's often used for critical components in cars, airplanes, and medical devices.

Squeeze Die Casting:

Combining pressure and heat, this method creates parts with superior mechanical properties and minimal shrinkage. It's widely used in automotive systems like suspension components and gearboxes.

Semi-Solid Die Casting:

Perfect for intricate shapes without defects, this technique is favored in industries requiring advanced engineering solutions, such as automotive and electronics.

Advantages of Die Casting

High Production Efficiency: Die casting is perfect for large-scale production, offering quick turnaround times.

Material Versatility: Supports a variety of metal alloys, including aluminum, zinc, and magnesium.

Precision: Produces parts with high dimensional accuracy and complex geometries, especially when using CNC-machined molds.

Complex Details: Capable of manufacturing parts with intricate features like embedded threads and thin walls.

Smooth Surface Finish: low-pressure and semi-solid casting can produce smooth surfaces, minimizing the need for secondary machining.

Long Mold Life: Molds are typically made from durable steel, ensuring longevity even under high pressure and temperature conditions.

Limitations of Die Casting

Not Ideal for Small Batches: The high initial cost makes it less suitable for small-scale projects.

Material Restrictions: Die casting typically uses non-ferrous metals like aluminum, zinc, and magnesium, as iron is not suitable.

High Mold Costs: Creating molds, especially for complex parts, can be expensive.

Potential Defects: Issues like porosity, shrinkage, or surface imperfections may occur if not properly managed.

Comparison with Other Manufacturing Methods

Sand Casting: Die casting offers higher precision but comes at a higher cost.

CNC Machining: While CNC machining is better suited for simple shapes and small batches, die casting excels in complex designs and large-scale production.

Injection Molding: Injection molding works well for plastics, whereas die casting focuses on non-ferrous metals. Injection molding has shorter cooling times and lower mold costs.

Forging: Forging uses compressive forces to shape metal, making it suitable for both ferrous and non-ferrous metals. Forged parts have better mechanical strength, but die casting offers superior precision.

Applications of Die Casting

Appliances Industry: Manufactures various components for household and commercial appliances.

Renewable Energy Industry: Produces durable parts for wind turbines and solar systems, such as housings and supports, using corrosion-resistant aluminum and magnesium alloys.

Automotive Industry: Creates engine parts (e.g., cylinder heads, transmission cases) and body components (e.g., wheels, door handles) with lightweight aluminum, zinc, and magnesium alloys.

Electronics Industry: Generates precise parts like connectors, heat sinks, and enclosures for electronic devices.

Consumer Goods: Efficiently produces everyday items like kitchen appliances, power tools, and hardware, leveraging high productivity and cost-effectiveness.

Construction Industry: Designs functional and aesthetic components, including hinges, window frames, and fixtures, with complex geometries.

How to minimize defects in die casting?

To ensure high-quality die-cast parts, it's important to address common defects like porosity, shrinkage, and surface imperfections. Here are some effective strategies:

Optimize Mold Design: Ensure smooth metal flow and uniform cooling by designing molds with proper vents and overflow channels. This helps prevent issues like uneven cooling and warping.

Use Vacuum Die Casting: By creating a vacuum environment, this technique reduces air entrapment and improves part density, resulting in stronger components.

Control Process Parameters: Carefully manage factors such as temperature, pressure, and injection speed. Proper control minimizes turbulence and prevents defects caused by improper melting or injection.

Implementing these steps can significantly reduce defects, improving both part quality and production efficiency. This is especially crucial in industries like energy, automotive, and electronics, where precision is key.

Key Design Considerations

To optimize part quality and manufacturing efficiency, consider the following factors during the design phase:

Draft Angle: Add slight angles to facilitate easy removal of parts from the mold.

Fillet Radii: Use rounded corners to reduce stress concentrations; recommended minimum radius is 0.4mm.

Parting Line: Ensure the parting line is straight and doesn't interfere with part functionality.

Wall Thickness: Maintain uniform thickness to avoid shrinkage voids and defects.

Bosses: Properly design these protrusions for mounting purposes, considering diameter, height, and wall thickness.

Ribs: Add ribs to increase strength without adding weight, carefully selecting size and spacing.

Holes and Windows: Carefully plan their dimensions and positions to prevent defects.

FAQs About Die Casting

Q1: How to Calculated The Cost?

The cost of die casting depends on several factors:

Mold Cost: A one-time investment that can be spread across large production runs.

Material Cost: Different alloys vary in price; for example, zinc alloy is generally cheaper than aluminum.

Production Volume: Larger volumes significantly reduce per-unit costs.

Secondary Operations: Additional processes like CNC machining or surface treatments (e.g., anodizing, painting) add extra costs.

Q2: What Is the Production Lead Time?

Overall lead time varies based on project requirements and production scale.The production timeline includes two main stages:

Mold Development: Typically takes 4–12 weeks depending on part complexity and mold size.

Actual Production: Once the mold is ready, die casting is very fast, producing 50–400 parts per hour depending on part size and equipment.

Q3: Do You Support Prototyping or Small-Batch Production?

Yes! While die casting is most cost-effective for large-scale production, we also support prototyping and small-batch runs using rapid prototyping techniques like 3D-printed molds.

Q4: Do You Offer Sample Testing?

Absolutely! Before full-scale production, we provide sample testing to validate design and functionality, ensuring the final product meets your expectations.

Q5: Do You Provide Post-Casting Services?

Yes, we offer comprehensive post-casting services, including CNC machining, surface treatments (anodizing, painting, plating), and assembly. These services streamline your supply chain and shorten delivery times.

Future Trends in Die Casting Technology

As technology advances, die casting continues to evolve:

New Material Development: High-strength aluminum and magnesium alloys are being developed for improved performance.

Environmental Sustainability: Efforts are underway to reduce energy consumption and minimize waste generation.

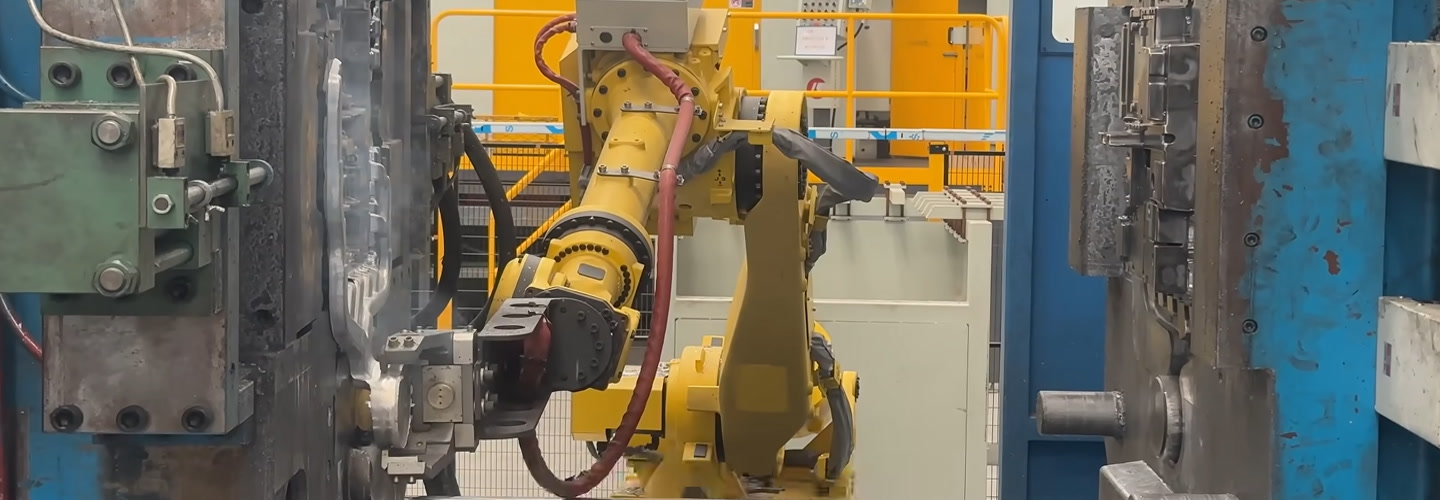

Digitalization and Automation: Advanced automation and digital tools enhance production efficiency and quality control.

Conclusion

Die casting is a versatile and efficient manufacturing process with countless applications across industries. Whether you're producing automotive parts, electronics, or consumer goods, die casting offers the precision and scalability needed for success.If you have any questions or need assistance with your next project, feel free to reach out—we're here to help!