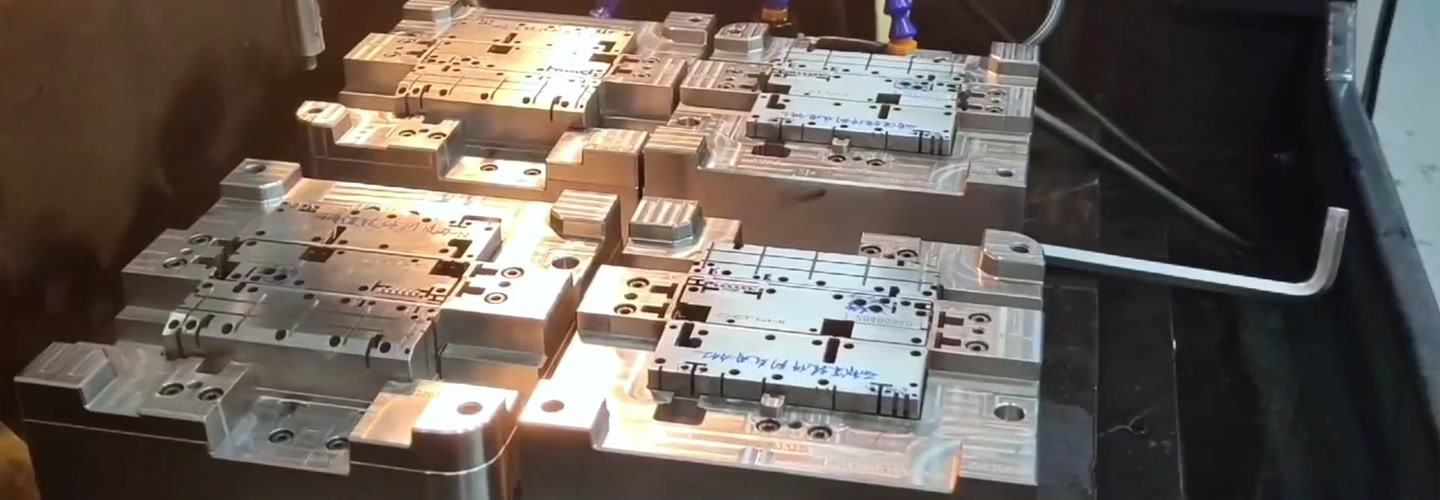

The success of a product in modern manufacturing is determined not only by its appearance but also by production efficiency, cost control, and sustainability. In injection molding, mold surface treatment holds a critical role, as it directly influences the quality, performance, and efficiency of the final product.

Why Is Mold Surface Treatment Important?

The condition of a mold's surface is directly transferred to the plastic product. For example, a smooth mold surface results in shiny products, while a rough surface adds unique textures. Additionally, mold surface treatments influence key properties such as demolding performance, wear resistance, and corrosion resistance. Considering these factors early in product development helps customers avoid costly modifications later.

Common Mold Surface Treatment Methods and Applications

Polishing

Polishing makes the mold surface extremely smooth, usually using diamond tools or fine sandpaper. This method is ideal for products requiring high gloss, such as premium electronic device casings.

Advantages: Improves visual appeal and reduces surface defects.

Challenges: The polishing process may increase manufacturing time and costs, especially for molds with complex geometries.

Customer Case: We helped an electronics company optimize the polishing process for their smartphone cases. By adjusting the polishing parameters, we improved the product's shine and reduced bubble issues during injection molding, lowering waste rates.

Blasting

Blasting involves spraying glass beads or aluminum oxide particles at high pressure onto the mold surface to create uniform textures. This technique is often used for products that need slip resistance or specific tactile effects.

Environmental Consideration: Using recyclable blasting materials (like glass beads) reduces environmental impact.

Application Example: Sports equipment (e.g., yoga mats) and industrial parts (e.g., handles) commonly use blasting to enhance grip and durability. Customer Case: A home goods manufacturer wanted to add anti-slip features to their plastic cups. We recommended blasting with renewable material-based particles, which not only met functional requirements but also reduced the carbon footprint.

Coating

Coating applies a protective layer to the mold surface to enhance wear resistance, corrosion resistance, or improve demolding performance. Some metal coatings significantly extend mold life and reduce maintenance frequency.

New Coating Materials: Eco-friendly coatings, such as water-based or biodegradable coatings, are becoming more popular. These coatings meet high-performance requirements while reducing environmental burdens.

Practical Effect: Coatings protect molds and reduce the likelihood of plastic sticking during injection molding, minimizing waste.

Customer Case: An automotive parts manufacturer faced challenges with brake disc wear. We introduced a special coating technology that improved wear resistance and included self-cleaning properties, reducing cleaning steps and boosting production efficiency.

Chemical Etching

Chemical etching uses chemical reactions to create intricate patterns on the mold surface. This method is suitable for products needing personalized decorations, such as luxury packaging or custom parts.

Precision Control: Modern etching techniques combined with CAD software allow for highly complex designs, meeting high-end market demands. Environmental Improvement: Some manufacturers are researching eco-friendly chemicals to replace traditional corrosive agents, reducing pollution. Customer Case: A gift packaging company sought unique decorative effects for their products. We customized complex floral patterns using chemical etching, enhancing both aesthetics and production quality.

How Surface Treatments Impact Product Development ?

Choosing the right surface treatment offers several benefits:

Cost Reduction: Reducing mold wear and maintenance extends its lifespan.

Improved Efficiency: Better surface treatments speed up the demolding process and shorten production cycles.

Enhanced Competitiveness: Unique and high-quality surface effects make products stand out in the market.

Sustainability Promotion: Using eco-friendly materials and technologies reduces resource waste and environmental impact.

Future Trends and Outlook

As global attention to sustainability grows, new technologies and materials are emerging in the field of mold surface treatment. Here are some trends worth noting:

Intelligent Surface Treatment

Combining artificial intelligence and big data analysis, future surface treatment technologies will automatically adjust parameters based on product needs, achieving higher precision and efficiency.

Eco-Friendly Material Development

Developing more degradable and recyclable surface treatment materials will be a key direction for the industry. This reduces resource waste and helps companies comply with environmental regulations.

Multi-Functional Surface Treatment

New surface treatment technologies will no longer focus on single functions but integrate multiple characteristics, such as coatings with wear resistance, corrosion resistance, and antibacterial properties.

Conclusion

Mold surface treatment may seem like a small detail, but it has a profound impact on the entire production process. By carefully selecting and optimizing surface treatments, we can help customers improve product quality and performance, reduce costs, and enhance efficiency. Moreover, by integrating environmental considerations and technological innovations, we can drive the manufacturing industry toward a more sustainable future. Whether you're a designer or engineer, this step should be an essential part of your product development strategy.