Why Choose 3D Printing Over Traditional Methods?

Product development speed is crucial for maintaining a competitive edge. 3D printing, or additive manufacturing, is a revolutionary rapid prototyping technique that is transforming traditional manufacturing. It enables designers and engineers to quickly turn ideas into reality and offers new possibilities for customization, complex designs, and small-scale production.

What is 3D Printing Rapid Prototyping?

3D printing rapid prototyping is a process where three-dimensional objects are created by layering materials one at a time. Unlike traditional subtractive manufacturing methods like CNC machining, which involves cutting away material, 3D printing eliminates the need for complex tools or molds. Instead, it directly generates physical objects from digital models. This makes it ideal for creating prototypes, conducting functional tests, and producing small batches of products.

Core Advantages of 3D Printing

High Design Flexibility

Whether it's intricate geometries or hollow internal structures, 3D printing can easily bring them to life. This technology breaks free from the constraints of conventional manufacturing methods, giving designers the freedom to explore bold and creative ideas.

Rapid Iteration

From concept to finished product, 3D printing can produce a prototype within hours. This enables businesses to refine their designs multiple times in a short period, significantly reducing the development cycle.

Cost Efficiency

For small-scale production and prototyping, 3D printing is much more cost-effective than traditional methods. Without the need for expensive molds or tools, design changes can be implemented quickly by simply adjusting the digital file.

Wide Material Options

Modern 3D printing supports a variety of materials, including plastics, metals, ceramics, and even biomaterials. This broad range of options meets the diverse needs of consumer goods, industrial applications, and beyond.

Popular 3D Printing Technologies

Among the many 3D printing technologies available, stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), and multi-jet fusion (MJF) are some of the most commonly used methods, each with its own unique strengths and applications.

SLA (Stereolithography)

SLA uses UV light to cure liquid resin layer by layer, creating parts with exceptional precision and smooth surface finishes. It's perfect for appearance validation and detailed decorative pieces. For example, we worked with a jewelry designer to create intricate ring models using SLA technology, providing highly personalized customer service.

SLS (Selective Laser Sintering)

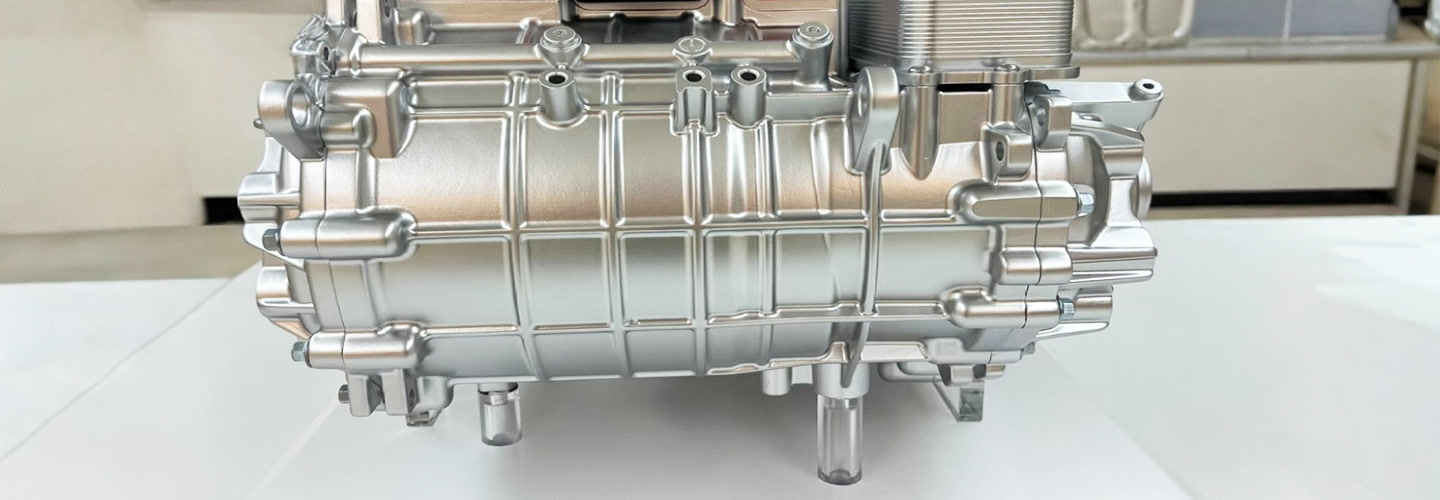

SLS employs lasers to fuse powdered materials into solid components, resulting in strong and durable parts. Since it doesn't require support structures, SLS is great for complex geometries and functional components. In one project, our team collaborated with an automotive manufacturer to produce lightweight interior parts using SLS, enhancing vehicle performance while maintaining structural integrity.

FDM (Fused Deposition Modeling)

FDM is an affordable 3D printing method that builds parts by heating and extruding plastic filament layer by layer. It's widely used in educational settings and early-stage prototyping. Recently, our company helped a startup leverage FDM to quickly create a prototype of a new coffee machine casing, significantly reducing their R&D time.

MJF (Multi Jet Fusion)

MJF is an efficient 3D printing technique that fuses powdered materials using heat activators and infrared lamps. It boasts excellent mechanical properties and high production speeds, making it suitable for large-scale production of functional parts. For instance, our company partnered with a sports brand to manufacture customized shoe soles using MJF, improving both comfort and performance for their customers.

Comparing 3D Printing with Other Rapid Prototyping Techniques

Besides 3D printing, there are other popular rapid prototyping techniques, such as CNC machining and vacuum casting. CNC machining is a subtractive manufacturing process that cuts and shapes materials using computer-controlled tools. It offers high precision, especially for metal parts, but struggles with complex geometries and is often too costly for small-scale production or prototyping.

Vacuum casting, on the other hand, is a replication technique that uses silicone molds and polyurethane materials to duplicate master models. It's cost-effective for small-scale production and provides good surface quality. However, its mold lifespan is limited, and it lacks flexibility for frequent design changes.

In contrast, 3D printing stands out with its high design flexibility, rapid iteration, and no need for molds, making it particularly suitable for prototyping and complex structure manufacturing. While certain 3D printing technologies may still have higher costs and limited material options, they offer significant advantages depending on specific needs.

Client Case Study

Consumer Electronics

Our company worked with a leading headphone manufacturer to develop lightweight, durable earpieces using 3D printing. This reduced material waste and production costs, showcasing our ability to deliver innovative solutions.

Home Goods

We partnered with a furniture company to create a chair with a complex lattice structure using SLS technology. We produced functional prototypes quickly, enabling small-scale production and highlighting our expertise in complex designs.

Toy Industry

Collaborating with a toy manufacturer, we used FDM technology to design personalized building blocks for children. The final products, recognized for their vibrant colors and versatility, became popular among kids.

Future Trends in 3D Printing

As technology advances and new materials emerge, 3D printing is expanding its potential. Innovations like multi-material and smart materials are shaping a more efficient and sustainable future.

Whether you're designing custom jewelry, creating innovative furniture, or developing engaging toys, we will leverage the latest 3D printing technologies to bring your vision to life with precision and creativity. Contact us today to get started!