CNC machining stands out as one of the most reliable methods available. Whether you are developing a new product or refining an existing design, CNC machining offers numerous advantages that make it a top choice for manufacturers and innovators alike.

Speed

One of the biggest advantages of CNC machining is its speed. Once your design is ready in CAD format, it can be transformed into a physical prototype within hours or days, depending on complexity. Unlike other methods like injection molding, which require lengthy setup times for molds, CNC machining skips these steps entirely, allowing you to test and iterate faster.

For example, a client in the industrial sector needed a replacement gear for their production line. Using CNC machining, we delivered the part within 24 hours, minimizing downtime and ensuring smooth operations.

Material

Options CNC machining works with almost any solid material, giving you endless possibilities when it comes to choosing the right material for your prototype. Metals like aluminum, stainless steel, brass, and even exotic alloys are all viable choices. Plastics such as ABS, nylon, and polycarbonate are also commonly used.

This versatility means you can choose the best material for each stage. For instance, a power tool manufacturer worked with us to test a handle design using nylon for ergonomics evaluation before switching to aluminum for the final, durable version.

Cost Efficiency

While some manufacturing techniques require expensive tooling or molds, CNC machining eliminates these upfront costs. This makes it especially cost-effective for small batches or one-off prototypes. You only pay for the material and machine time, keeping expenses low while still achieving high-quality results.

A kitchen appliance startup partnered with us to produce their initial batch of blender blade prototypes using CNC machining. They saved significantly on tooling costs and were able to refine the design quickly.

Precision

CNC machining truly excels in its ability to deliver precise results. With tolerances down to fractions of a millimeter, you can be confident that your prototype will accurately match your design specifications. Additionally, since the process is computer-controlled, it ensures consistent quality across multiple parts.

We worked with a photography equipment company that needed a camera mount with tight clearances and intricate slots. Our CNC machining ensured every dimension was exact, meeting their demanding standards for professional-grade products.

Flexibility

Whether you need one part or fifty, CNC machining scales effortlessly to meet your needs. There's no additional cost for producing smaller quantities, which is perfect for startups or businesses testing new ideas.

An electronics firm approached us to produce five custom brackets for their latest device. Each bracket had slight variations based on user feedback. Thanks to CNC machining’s flexibility, we delivered all five units within a week, enabling them to quickly adapt their design.

Versatility

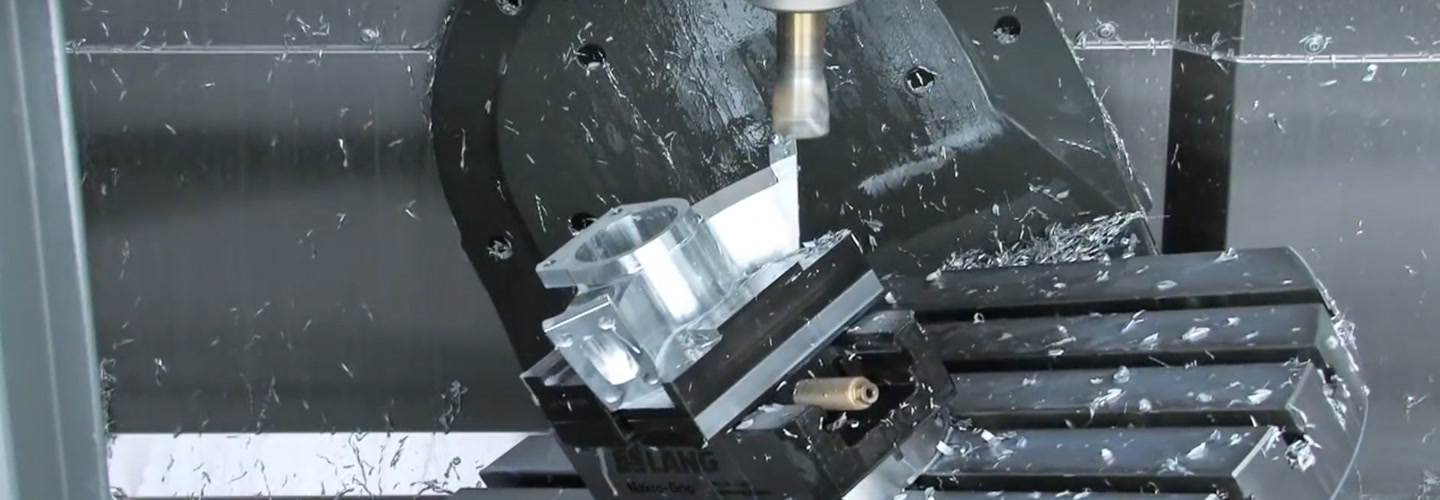

Modern CNC machines come equipped with advanced features like multi-axis capabilities, allowing them to handle even the most complex designs. By rotating the workpiece during cutting, they can create curved surfaces, angled cuts, and other challenging geometries without requiring additional setups.

An electronics firm approached us to produce five custom brackets for their latest device. Each bracket had slight variations based on user feedback. Thanks to CNC machining’s flexibility, we delivered all five units within a week, enabling them to quickly adapt their design.

Surface Finish

The surface finish produced by CNC machining often requires little to no post-processing. By selecting the right tools and settings, you can achieve smooth, polished finishes that look professional right out of the machine.

A consumer goods client worked with us to create prototypes for their latest product launch. The CNC-machined parts were so polished that attendees at a trade show assumed they were final products, enhancing the client’s brand image and generating positive feedback.

How to Choose The Right Rapid Prototyping Method?

When choosing a rapid prototyping method, it's important to understand the strengths of each technology. Here's a straightforward comparison of CNC machining, 3D printing, and vacuum casting:

CNC Machining

CNC machining is a subtractive process that cuts materials into precise shapes. It's ideal for high-precision parts with excellent surface finishes.

Precision: Perfect for complex geometries and tight tolerances, unlike 3D printing which may lack fine detail.

Materials: Works with metals, plastics, and composites—more versatile than 3D printing or vacuum casting.

Finish: Produces smooth surfaces without extra steps, whereas vacuum casting often needs post-processing.

Example: Ideal for making durable gears or industrial components.

3D Printing

3D printing builds objects layer by layer, offering flexibility for quick concept models and complex designs.

Speed: Great for rapid prototyping but lacks the strength and precision of CNC machining.

Complexity: Can create intricate internal structures that CNC machining cannot easily replicate.

Materials: Limited to plastics, resins, and some metal powders, unlike CNC machining's wide range.

Example: Perfect for testing early design ideas or lightweight drone parts.

Vacuum Casting

Vacuum casting uses silicone molds to produce small batches of parts with flexible materials and detailed textures.

Batch Production: Cost-effective for dozens to hundreds of parts, unlike CNC machining which is better for single pieces.

Materials: Supports soft-touch silicones and rigid polyurethanes, ideal for flexible components.

Textures: Transfers detailed surface textures directly, unlike CNC machining which may require additional steps.

Example: Suitable for creating phone cases or consumer product casings with grippy surfaces.

Each method has its own advantages. Choose CNC machining for precision, 3D printing for speed and complexity, or vacuum casting for small batches and flexible materials.

Conclusion

CNC machining offers unparalleled speed, precision, and flexibility for rapid prototyping, making it an excellent choice for a wide range of industries. From automotive to medical devices, electronics to consumer goods, its versatility ensures it meets virtually any requirement.