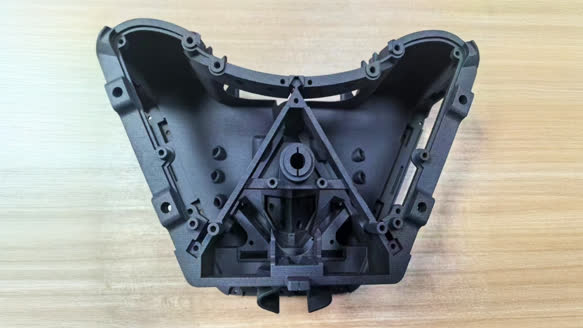

Creates functional prototypes and end-use parts layer-by-layer using SLA, SLS, or SLM technologies. Enables complex internal structures and design iterations for automotive prototypes, custom robotics parts, and IoT device housings within 24-48 hours.

3D Printing Services

Capabilities and Service

Our advanced 3D printing technologies efficiently transform your 3D files into plastic, metal, and elastomer parts, delivering outstanding results at competitive prices. Using advanced 3D printers, we reliably produce parts within days.

In addition to our extensive material selection, we provide various post-treatment options to enhance both appearance and mechanical properties. We also offer other rapid prototyping processes, including CNC machining and polyurethane vacuum casting. With Yes Prototype ,you get superior quality, speed, and versatility service tailored to your specific needs.

Main 3D Printing Services

We offer a comprehensive suite of 3D printing services tailored to meet a wide range of applications, from rapid prototyping to detailed functional parts. Our technologies include Stereolithography (SLA), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Each technology is selected based on specific project needs, ensuring optimal results for every application.

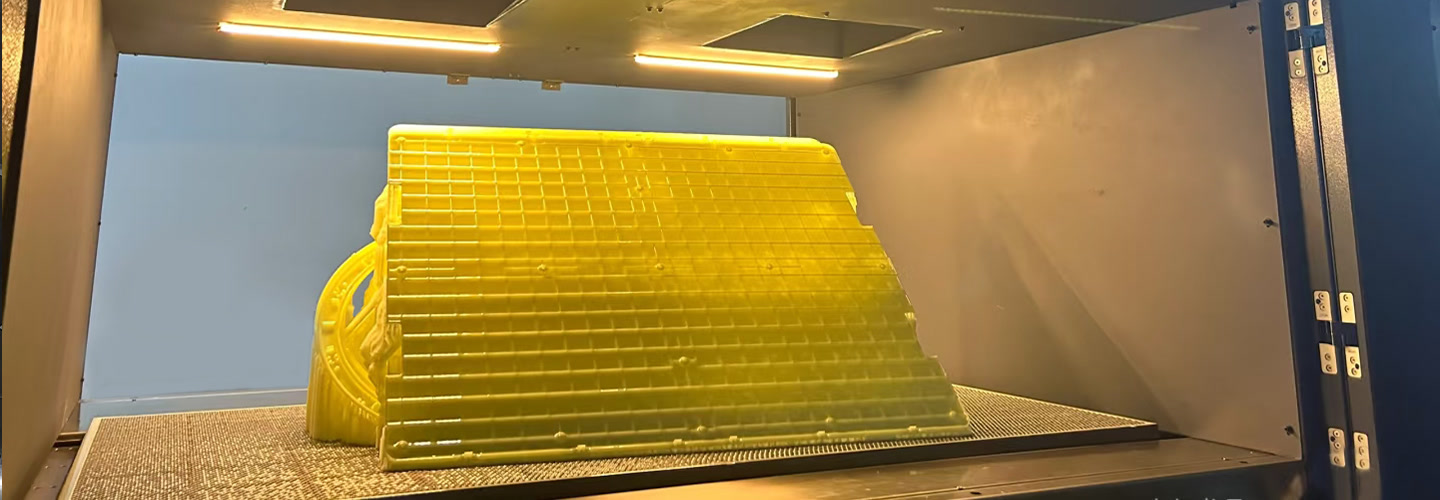

Stereolithography (SLA)

SLA offers rapid turnaround times as fast as one day, with over 10 materials, more than 26 colors, and 10 surface finishes. It achieves a tolerance down to ±0.1mm and can build parts up to 1.7m x 0.8m x 0.8m.

Selective Laser Sintering (SLS)

SLS provides production in as quick as three days using over five materials, eight surface finishes, with a tolerance down to ±0.1mm. Maximum build dimensions are 670 x 500 x 450mm.

Fused Deposition Modeling (FDM)

FDM delivers swift results within one day, utilizing more than 30 materials, over 26 colors, and 10 surface finishes. It maintains a tolerance of ±0.2mm and accommodates builds up to 1m x 1m x 1m.

Direct Metal Laser Sintering (DMLS)

DMLS ensures metal parts can be produced in as few as three days, with over five material options, eight surface finishes, achieving tight tolerances down to ±0.1mm and build sizes up to 500 x 500 x 500mm.

Multi Jet Fusion (MJF)

MJF offers efficient production within three days, providing more than five materials, eight surface finishes, with precision tolerances down to ±0.1mm and maximum part dimensions of 380 x 280 x 380mm.

Available 3D Printing Materials

FDM Printing

FDM printing uses a variety of plastics, including standard materials like ABS, PETG, and PLA; engineering plastics such as ASA, PC, and PC-ABS; high-performance options like PEEK; bio-medical plastics like PEEK; ESD-safe plastics like ESD-ABS; flame-retardant materials like PC-FR; outdoor-durable plastics like ASA and PC; waterproof options like PETG and PEEK; and carbon fiber-reinforced materials.

SLA/DLP Resins

SLA and DLP resin printing utilizes low-cost standard resins, high-performance functional resins like Somos® Evolve and Tough Resin, flexible TPU (Shore 65A), high-detail resins, high-temperature resistant resins like Craft-H (140°C) and Somos® PerFORM (250°C), and biomedical-specific resins.

SLS Materials

SLS technology primarily uses nylons like PA11 and PA12, reinforced with glass-filled options such as PA6+CF and PA12+CF, carbon-filled PA12+CF, and biocompatible PA2200 (PA12).

MJF Printing

MJF printing focuses on nylons such as PA11 and PA12, offering glass-filled options like PA12+CF, and ensuring skin-friendly properties with PA12.

DMLS Metals

DMLS metal printing provides a range of metals from popular choices like Aluminum and Stainless Steel 316 to high-performance materials such as Nickel Alloy and Titanium, medical-grade Ti64-Grade 5 and cobalt-chrome, and tool steel like Maraging Steel.

3D Printing VS CNC Machining VS Vacuum Casting

When choosing the right process for rapid prototyping, understanding the strengths and limitations of each method—3D printing, CNC machining, and vacuum casting—is crucial. Below is a detailed comparison focusing on materials and availability, accuracy and surface quality, as well as cost, quantity, and delivery time.

Materials and Availability

3D Printing

This method uses a variety of materials such as liquid photopolymer resin (SLA), plastic or metal powder (SLS/DMLS), and plastic filament (FDM). It generates minimal waste compared to traditional methods, making it environmentally friendly. Ideal for creating complex geometries and parts with specific material properties, 3D printing offers versatility in material selection tailored to unique design needs.

CNC Machining

CNC machining can handle almost any solid material, including production-grade engineering plastics and various metals. However, this subtractive process results in lower material utilization rates due to cutting from a solid block. Despite this, its broad material compatibility makes it an excellent choice for high-functionality prototypes and end-use parts that demand exceptional performance.

Vacuum Casting

Utilizing polyurethane resins available in multiple hardnesses, vacuum casting allows for the creation of soft rubber shapes and parts that closely resemble production-grade plastics. There is no minimum order quantity, making it suitable for small batch production, typically up to about 50 copies per mold. This method eliminates the need for costly metal tools, offering flexibility in low-volume manufacturing.

Accuracy, Surface Quality, and Geometric Complexity

3D Printing

Capable of producing highly intricate geometries, including hollow structures unachievable through other methods, 3D printing technologies like SLA provide high precision and excellent surface finishes. DMLS achieves tight tolerances down to ±0.1mm, ideal for precise functional metal components.

CNC Machining

Offering the highest dimensional accuracy (±0.005mm) and superior surface finishes (Ra 0.1μm), CNC machining excels in creating parts with stringent tolerance requirements. Advanced 5-axis CNC milling machines further enhance the ability to produce complex geometries with unparalleled precision. Vacuum Casting

Delivering good dimensional accuracy and high-quality surface finishes, vacuum casting supports detailed finishing options such as painting and polishing. While limited by mold life (typically around 50 copies), it is well-suited for parts requiring complex internal structures and aesthetic finishes.

Cost, Quantity, and Delivery Time

3D Printing

Economical for small quantities, 3D printing enables quick turnaround times with minimal human intervention. Costs are primarily based on material usage, making it cost-effective for smaller parts and batches. This method is particularly advantageous for rapid prototyping and small-scale production runs.

CNC Machining

Although initial setup costs are higher due to the need for specialized programming and skilled engineers, CNC machining becomes highly efficient for large-volume production. Once programmed, CNC machines can operate continuously without supervision, optimizing productivity for high-volume manufacturing.

Vacuum Casting

With moderate costs and no requirement for expensive metal tools, vacuum casting is ideal for small batch production, typically up to 50 parts per mold. The process ensures fast delivery times for custom parts and prototypes, balancing cost-effectiveness with quality output.

Why Choose Us ?

We provide efficient and tailored solutions for both rapid prototyping and large-scale production needs. By choosing us, you benefit from a wide range of materials and high-quality standards, supported by exceptional customer service.

Wide Range of Materials

We offer over 30 metal and plastic materials, ensuring the perfect fit for your project needs. From durable plastics to high-performance metals, our extensive selection caters to a variety of industries.

Quality Standards and Certifications

Our services are ISO 90012015 and ISO 13485 certified, ensuring top-notch quality and compliance. We deliver prototypes with excellent accuracy and surface finishes suitable for rigorous testing.

Advanced Manufacturing Capabilities

Equipped with over 20 advanced 3D printers from leading brands, we produce parts quickly and reliably. This capability allows us to handle both small and large production runs efficiently.

Rapid Prototyping and Efficient Delivery

We can deliver parts in as little as one day, accelerating your product development cycle. Our services are ideal for small batch production without the need for expensive metal tools.

Professional Engineering Support

Our team of engineers and project managers work closely with you to verify CAD designs and ensure product functionality. We provide comprehensive support throughout the entire process, from design evaluation to final certification.

Customizable Post-Treatment Options

We offer various post-treatment options such as surface treatments, painting, and polishing to enhance part appearance and durability. Custom finishes tailored to your specific requirements are also available.

Get Your 3D Printing Project Started Today

After receiving your CAD drawings, our engineers will analyze your custom parts immediately. We’ll work closely with you to clarify all details before providing a quote that is both economical and accurate.