Produces lightweight, high-strength aluminum/zinc alloy parts with complex geometries and thin walls (down to 1.2mm) for automotive systems and industrial machinery. Ensures rapid cycle times and dimensional stability (<0.05mm tolerance) for high-volume orders.

High Pressure Die Casting Service

From Medium-Volume to High-Volume Production

Yes Prototype offers a complete high pressure die casting solution designed to meet your product development needs. We specialize in crafting superior casting dies and components, and also provide CNC machining, plating, anodizing, powder coating, and other manufacturing services necessary for finishing your products.

What Is High Pressure Die Casting?

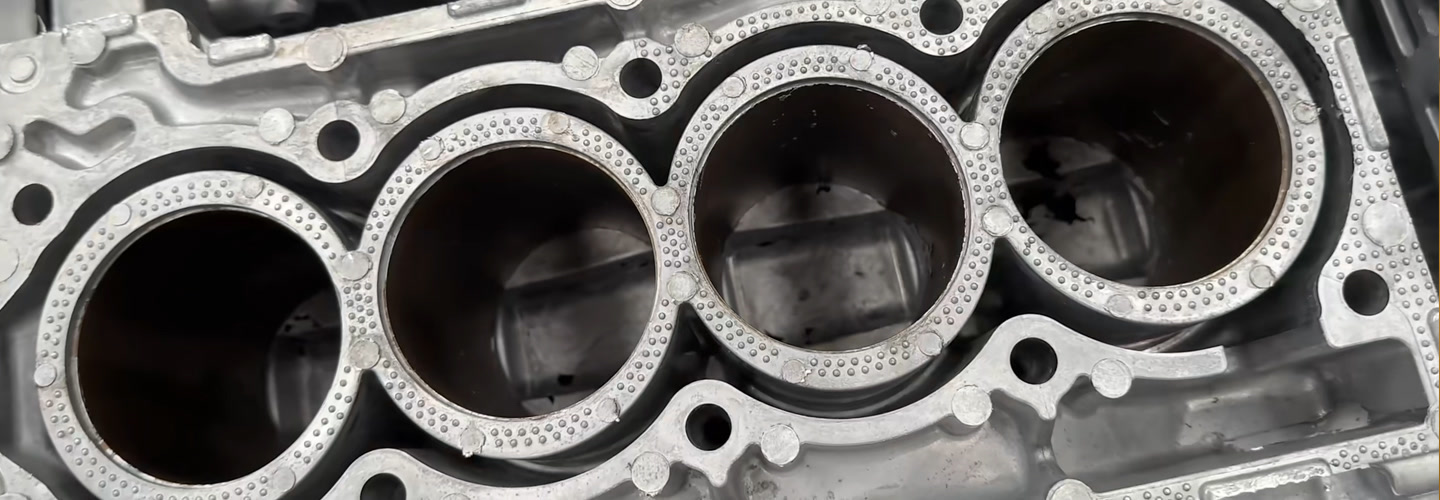

Die casting is a process where molten metal is injected into a mold under high pressure. Once the metal cools and solidifies, the mold opens, and the finished part is removed. This technique is widely used to create complex, high-precision components that are both durable and lightweight.

The process starts with designing a custom steel mold tailored to the specific requirements of the part. Molten metal, typically aluminum, zinc, or magnesium alloys, is then forced into the mold at high pressure. After cooling, the part is ejected, ready for use or further finishing.

How Does Die Casting Work?

The basic principle of die casting involves three key steps:

Preparation: A mold is prepared and coated to ensure smooth release of the final product.

Injection: Molten metal is injected into the mold cavity under intense pressure.

Cooling and Ejection: The metal cools and hardens inside the mold before being ejected.

Advantages of High Pressure Die Casting

Die casting offers numerous advantages over other manufacturing methods:

High Production Speed: Ideal for large-scale orders, ensuring quick turnaround times.

Material Versatility: Supports a wide range of non-ferrous metals, offering flexibility for diverse projects.

Precision and Complexity: Creates detailed parts with tight tolerances, reducing the need for secondary machining.

Cost-Effectiveness: Lower per-unit costs when producing in bulk.

Long Mold Life: Durable molds made from high-quality steel ensure consistent results over thousands of cycles.

Key Materials for Die Casting Applications

Different alloy materials are used in die casting to create parts with specific properties for various applications. Here’s an overview of the most common materials and their uses:

Aluminum Alloys: Lightweight, strong, and corrosion-resistant, ideal for automotive, aerospace, and electronics.

Magnesium Alloys: Extremely light, perfect for weight-sensitive applications like portable devices.

Zinc Alloys: Low melting point and easy to form, making them suitable for small, detailed parts.

Copper Alloys: High strength and excellent conductivity, suitable for electrical components and bearings.

Tin Alloys: Easy to shape, often used for decorative items and jewelry.

Lead Alloys: Soft and dense, commonly used for radiation shielding.

When choosing a material, consider factors such as part function, environmental conditions, and cost. If you're unsure which material is best for your project, feel free to contact us for guidance.

Why Choose Us?

At Yes Prototype, we provide advanced forming dies to produce precision-finished metal parts. Here are several reasons why thousands of companies and engineers choose to work with us.

One-Stop Solution

We offer comprehensive services from design support to machining features like threaded holes, machined surfaces, and o-ring grooves, and other complex features. Our engineers team will optimize your product designs to achieve maximum efficiency and product performance.

Quality Control

Experienced engineers on our team use advanced measuring and testing equipment to verify all materials used in high pressure die casting services, ensuring high quality and meeting customer expectations through meticulous inspection processes.

Services Support

We offer competitive pricing with no minimum order requirements and deliver quotes within 48 hours.

Begin Your Die Casting Project Today

After receiving your 3D drawings, our engineers will analyze your custom parts immediately. We’ll work closely with you to clarify all details before providing a quote that is both economical and accurate.