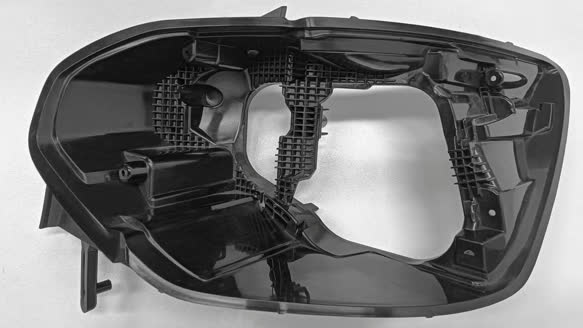

Produces high-volume plastic parts using thermoplastics or elastomers in custom molds, ensuring repeatability for automotive housings, consumer electronics casings, and industrial components. Delivers ±0.05mm tolerances and surface finishes from matte to glossy textures.

Plastic Injection Molding Services

At Yes Prototype, we specialize in producing high-quality plastic injection-molded parts and mold tools. Our comprehensive manufacturing solutions cover raw material verification, tool making, part fabrication, finishing, and final inspection. Our skilled and experienced technicians provide professional support for projects of all sizes and complexities, ensuring quality throughout.

Injection Molding Tool Lead Time

The time required to make an injection mold tool depends on the complexity of the design and the material used. A simple shape, such as a basic square made from softer steel like P20, can be completed in under one week. Harder steels take longer to machine and heat treat, while more complex shapes or advanced surface textures may need three weeks or more to prepare.

Advantages of Injection Molding

Once a tool is made, plastic injection molding is the fastest and most cost-effective way of manufacturing hundreds of thousands of finished plastic parts. Molded parts have excellent surface finishes with reliable and repeatable dimensional tolerances. And there are resins available to suit most common applications.

Process of Plastic Injection Molding

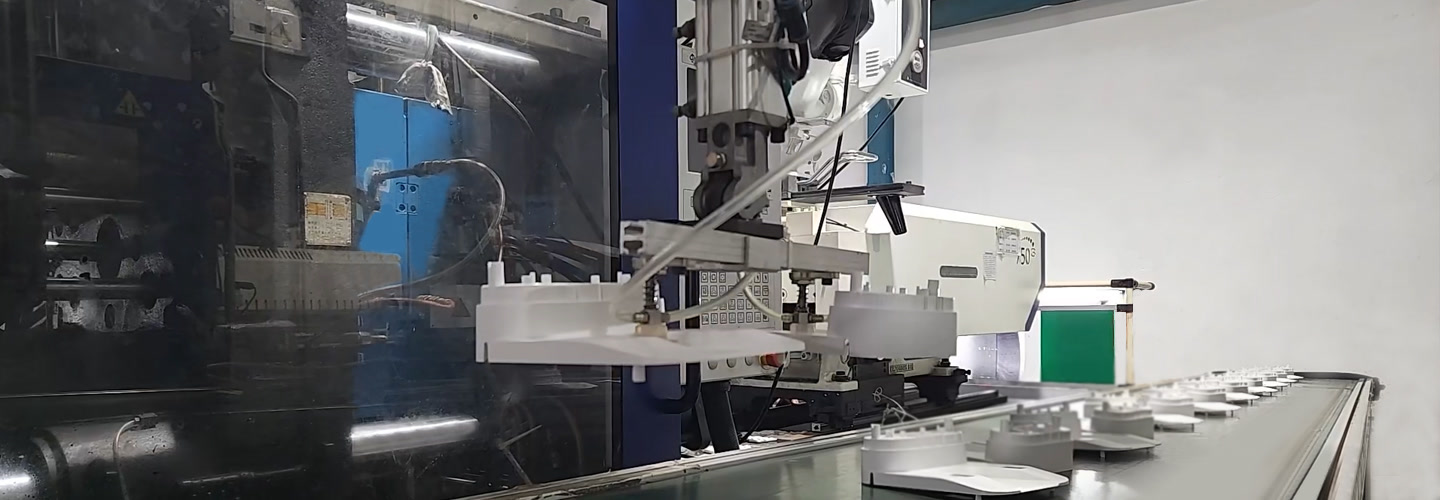

Plastic injection molding is a manufacturing method that involves filling a mold with liquid plastic resin under high pressure. The mold can have one or many cavities, allowing for the production of numerous parts. Once the mold has been carefully designed and built, the process follows these basic steps:

Material Preparation: The process starts with raw plastic resin in pellet form. These pellets are dried to the right moisture level, and if needed, mixed with pigments or colorants to get the desired color for the final product.

Feeding: The molding machine's hopper is filled with dried pellets. A reciprocating screw inside the barrel heats and moves these pellets toward the mold.

Melting: Inside the barrel, the pellets are mixed and heated until they melt completely, forming a liquid resin.

Injection: After the heated mold automatically closes, liquid resin under high pressure is fed into the mold cavity through a gate.

Cooling: The mold is then cooled for a short time to solidify the part inside.

Ejection: Finally, the mold opens, and the finished part is ejected, allowing the cycle to start again.

Which Kinds of Resins and Tools Are Available?

S136H, 2316H, H13 hardened, P20, 8407, and NAK80 semi-hardened steels are used to create our tools and dies. We provide a variety of etched textures, EDM texturing, and typical SPI finishes. Additionally, thousands of thermoforming plastics are available for your projects.

Material Selection for Plastic Injection Molding

The primary consideration when selecting a plastic is the part's intended use and the physical conditions it will encounter, such as temperature fluctuations, moisture, chemical exposure, UV light, and many more. The strength, durability, flexibility, color, and cost of the material are then factors to consider. For most parts, we use the 10 most popular plastic injection molding resins: ABS, PBT, PEEK, polyethylene (PE), polycarbonate (PC), polypropylene (PP), nylon (PA), acrylic (PMMA), polystyrene (PS), and TPE.

Why Choose Yes Prototype for Plastic Injection Molding ?

We utilize high-quality raw materials, implement rigorous process management, and have skilled toolmakers to produce the finest production mold tools. Our extensive experience enables us to deliver consistent results for your production tooling needs. Below are some benefits of Yes Prototype's plastic injection molding services.

Comprehensive Services

Each tool and product design project includes a comprehensive manufacturing review, where we identify potential issues such as thermal stress, shrinkage, warping, or other avoidable defects in your injection molded parts. This ensures you achieve excellent results while conserving both time and money.

Quality Assurance and Inspection

All incoming materials are carefully inspected and issue a complete verification analysis at your request. You will receive the sample inspection report and samples to confirm all dimensions and tolerances for your tools and finished parts.Key conditions, such as temperature and humidity, are meticulously controlled to ensure consistency during production. Additionally, we utilize 3D scanning technology for complex shapes to guarantee precision.

Advanced Production Capabilities

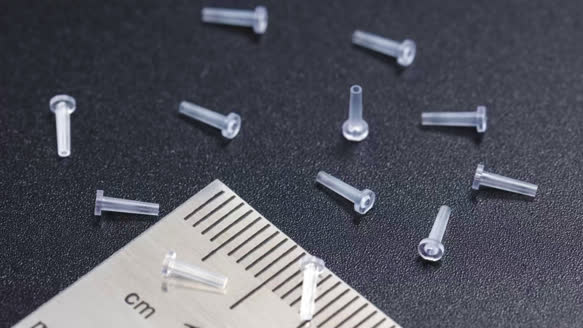

Our molding service is enhanced by significant experience and a wide range of production capabilities. Utilizing advanced facilities, we can manufacture parts that vary in size from millimeters to cubic meters.

Professional Support and Consultation

Experienced tooling technicians are available to offer you comprehensive support. We assist you through video calls and customer service to make sure we meet your needs efficiently.

Cost Savings

Process reliability, rapid cycle times, and manufacturing efficiency can all result in long-term savings. The relative cost of the tool decreases as production volume increases.

Tolerance Standard

We follow the DIN-16742 standard tolerances for injection molding to guarantee high quality in our manufacturing process. Maintaining rigorous standards is essential for achieving precision and dependability.

Efficiency Quotes

To support your development goals, we have no minimum order requirements. You will receive prompt and accurate pricing for each project.

Get a Quote for Injection Molding Right Now

After receiving your 3D drawings, our engineers will analyze your custom parts immediately. We'll work closely with you to clarify all details before providing a quote that is both economical and accurate.